-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

In the world of industrial applications, jaw crushers play a pivotal role in the processing of materials. With their robust structure and high efficiency, they have become a cornerstone in various sectors including mining, construction, and recycling. According to Dr. Emily Johnson, a renowned expert in mineral processing and machinery, “The jaw crusher is not just a tool; it is a vital component that enhances productivity and ensures the quality of output in industrial operations.”

The benefits of using jaw crushers extend beyond mere efficiency; they are essential for optimizing the crushing process and maximizing resource utilization. By breaking down large stones into manageable sizes, jaw crushers facilitate the subsequent processing stages, ultimately contributing to a more streamlined workflow. Additionally, their versatility allows for a range of applications, making them indispensable in various industrial contexts.

As industries continue to evolve, the significance of jaw crushers remains unwavering. Not only do they help in reducing material size, but they also foster sustainable practices by enabling recycling efforts. In the following sections, we will delve into the top ten benefits of using jaw crushers in industrial applications, exploring their impact on operational efficiency and economic viability.

Jaw crushers play a vital role in various industrial settings, primarily due to their robust design and unmatched efficiency in material processing. One of the key functions of jaw crushers is their ability to crush large rocks and ores into smaller, manageable sizes, thereby facilitating subsequent processing stages. According to a report by the Freedonia Group, the demand for jaw crushers in the mining and construction industries is expected to grow significantly, driven by the need for efficient aggregate production and mineral extraction. The performance of jaw crushers can lead to increased productivity, as they can process large quantities of material at a high rate, thereby reducing operational downtime.

In addition to their crushing capabilities, jaw crushers are also renowned for their versatility in various industrial applications. They can efficiently handle both hard and soft materials, making them suitable for diverse industries, including construction, mining, and recycling. A recent study by Research and Markets highlights that the global jaw crusher market is projected to reach $1.7 billion by 2025, reflecting the equipment's reliability in transforming raw materials into usable products. Furthermore, the sturdy construction of jaw crushers ensures a long service life, which significantly contributes to reduced maintenance costs and improved operational efficiency in industrial environments.

Jaw crushers are a cornerstone in industrial material processing due to their efficiency in crushing a variety of materials. One of the primary advantages of jaw crushers is their high crushing ratio, which can reach up to 6:1 for certain applications. This means they can break down larger stones into manageable sizes more effectively than many alternatives, enhancing overall material handling and processing times. According to a report by Grand View Research, the global market for jaw crushers is projected to grow significantly, demonstrating the increasing reliance on these machines for efficient material reduction in sectors such as mining, construction, and recycling.

Another compelling benefit is their ability to handle a wide range of materials, from hard rocks to recycled concrete. The design of jaw crushers allows them to crush materials with higher compressive strength, typically between 150 to 300 MPa. Moreover, their operational simplicity—characterized by fewer moving parts—leads to reduced maintenance costs and lower downtime. The Minerals Council Australia has highlighted that the longevity and reliability of jaw crushers play a crucial role in increasing throughput while minimizing operational interruptions, further solidifying their position as a preferred choice for crushing processes in various industries.

Jaw crushers have long been a cornerstone in the field of material processing due to their unmatched durability and low maintenance requirements. According to a recent industry report published by Market Research Future, the global jaw crusher market is projected to grow at a CAGR of 6.2% from 2020 to 2027, underscoring the equipment's reliability and preference in various industrial applications. Jaw crushers are engineered to withstand harsh operating environments, constructed from high-quality materials that ensure extended lifespan and reduced wear. This durability significantly lowers costs associated with frequent equipment replacements and repairs, making them a smart long-term investment for companies.

In terms of maintenance, jaw crushers require relatively minimal upkeep compared to other crushing machinery. The simple design and robust construction mean that the frequency of repairs is lower, which translates to more uptime and efficiency in operations. A study by Technavio indicates that scheduled maintenance and operational downtime could be reduced by nearly 30% with the effective use of jaw crushers. This benefit is particularly crucial in industries where continuous operation is key, such as mining and construction. By minimizing maintenance needs, facilities can optimize their workflow and focus resources on production rather than equipment management, driving overall productivity.

This chart illustrates the key benefits of using jaw crushers in industrial settings, highlighting their durability and maintenance advantages, which contribute to improved operational efficiency and reduced downtime.

Jaw crushers are invaluable tools across a spectrum of industries, showcasing their versatility in various applications. In construction, they are often employed to break down large boulders into manageable sizes for use in concrete and asphalt production. The ability to crush materials down to the desired size ensures that construction projects can proceed without delays caused by oversized aggregates. Similarly, in the mining industry, jaw crushers facilitate the extraction of valuable minerals by reducing ore materials for further processing, thereby enhancing overall efficiency.

When considering the versatility of jaw crushers, it's important to recognize their adaptability to different materials. Whether processing hard rocks, ores, or even recycled materials, jaw crushers can be configured to handle a wide range of tasks. This flexibility allows industries to use them in multiple stages of production without the need for extensive equipment changes.

Tips: To maximize the efficiency of jaw crushers, ensure regular maintenance checks are performed to avoid unexpected downtimes. Additionally, training operators on optimal techniques for loading materials can prevent excessive wear and tear on the machinery, thereby extending its lifespan. By tailoring operations to the specific tasks at hand, users can fully leverage the capabilities of these essential industrial tools.

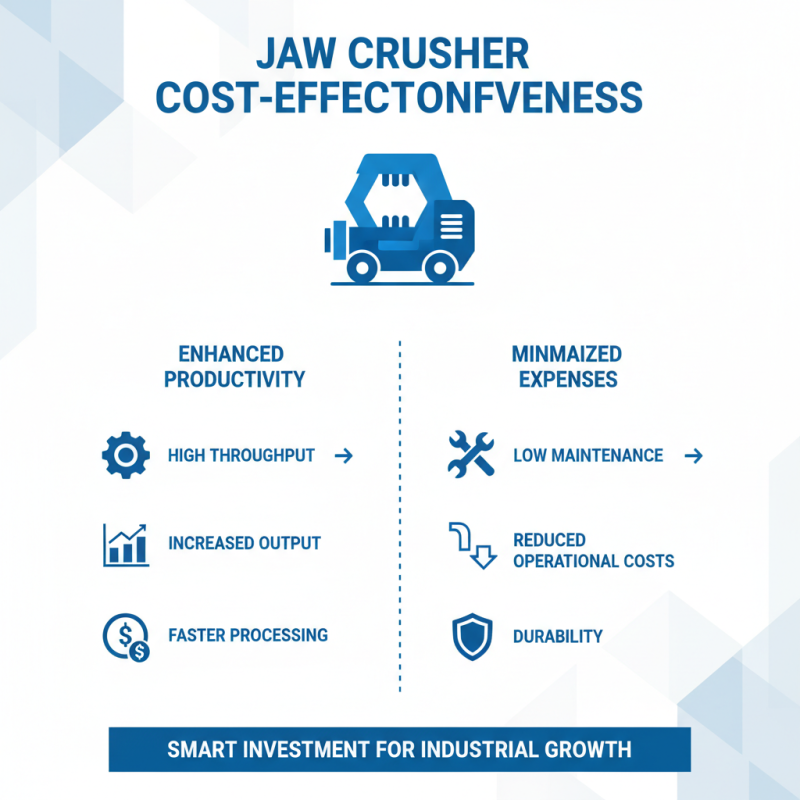

The cost-effectiveness of implementing jaw crushers in industrial operations is a significant consideration for businesses aiming to enhance productivity while minimizing expenses. Jaw crushers are renowned for their durability and efficiency, enabling them to handle various types of materials. This robust machinery requires relatively low maintenance, leading to reduced operational costs over time. Additionally, their ability to process high volumes of material quickly allows companies to achieve higher output levels, further justifying the initial investment.

Moreover, jaw crushers optimize resource utilization by ensuring that a maximum percentage of raw materials can be converted into usable outputs. This efficiency not only speeds up production timelines but also decreases waste, which translates to additional savings. The long-term benefits associated with jaw crushers, including their energy-efficient design and straightforward maintenance requirements, contribute to an overall lower total cost of ownership. As businesses strive to remain competitive, integrating such cost-effective solutions into their operations becomes essential for sustainable growth and profitability.