-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

In the world of construction, choosing the right equipment is vital. A Granite Crusher stands out for its efficiency and durability. According to the National Stone, Sand, and Gravel Association, the aggregate industry's contribution to the U.S. economy was $28 billion in 2021. As projects evolve, the demand for high-quality crushed granite increases.

These crushers are not just machines; they are foundational elements in construction. Their ability to produce granite aggregate impacts roads, buildings, and other infrastructures. A report from Freedonia Group shows that the global demand for crushed stone is projected to reach 16.5 billion metric tons by 2026. This highlights the need for reliable granite crushing solutions.

However, selecting the right granite crusher can be challenging. Various options offer differing capabilities and specifications. Some machines may excel in certain conditions but fall short in others. As construction demands rise, it’s crucial to reflect on the best choices available. Investing in a quality Granite Crusher today may define project success tomorrow.

When it comes to granite crushers, understanding the types and features is essential. Granite crushers generally fall into two categories: jaw crushers and cone crushers. Jaw crushers excel in crushing larger pieces of granite. They break the material down through a powerful compressive force. On the other hand, cone crushers are perfect for creating finer granules. Their design allows for more versatility in terms of the desired output size.

Features play a significant role too. A good granite crusher should offer durability and efficiency. Look for crushers with a higher crushing ratio. This feature means they can turn larger stones into smaller, usable materials more quickly. Some machines include advanced technology for better performance. Yet, there are models that may not meet all expectations. They might struggle with excessively hard granite or produce inconsistent sizes. It’s crucial to research and weigh the benefits versus limitations of each type.

Granite crushing can be a straightforward process, but not without challenges. The wrong equipment choice can lead to significant downtime. Overly complex features may add unnecessary difficulties. Simplicity should not be overlooked. Balancing power and ease of use is vital for optimal results in construction projects. Keeping these aspects in mind can help you make an informed decision.

This chart illustrates the different types of granite crushers and their effectiveness in terms of processing capacity (tons per hour) and cost efficiency (USD per ton). The data provides a comparative view to help you make informed decisions for your construction projects.

When selecting a granite crusher for your construction projects, consider the machine's design. Every crusher has unique features. Some are made for large-scale operations, while others suit smaller jobs. Performance matters; a balanced combination of power and efficiency is essential. Pay attention to the crusher's capacity and the size of granite it can handle comfortably.

Durability plays a crucial role, too. Granite is tough, and the crusher should match its strength. Look for machines made with high-quality materials. Regular maintenance is another factor. Some machines require more upkeep than others. This can impact your overall costs over time.

Moreover, ease of use is vital. Some models have complicated settings. This might slow down your operation. Opt for user-friendly designs that enhance productivity. It's worth pondering if the performance trade-offs are acceptable in your context. In construction, every choice matters; make sure yours is the best fit for your needs.

| Feature | Option A | Option B | Option C |

|---|---|---|---|

| Crushing Capacity (tons/hour) | 50 | 75 | 120 |

| Power Requirement (kW) | 55 | 75 | 110 |

| Weight (kg) | 8,000 | 10,500 | 15,000 |

| Max Feed Size (mm) | 300 | 400 | 500 |

| Price Range (USD) | $40,000 - $50,000 | $60,000 - $75,000 | $90,000 - $120,000 |

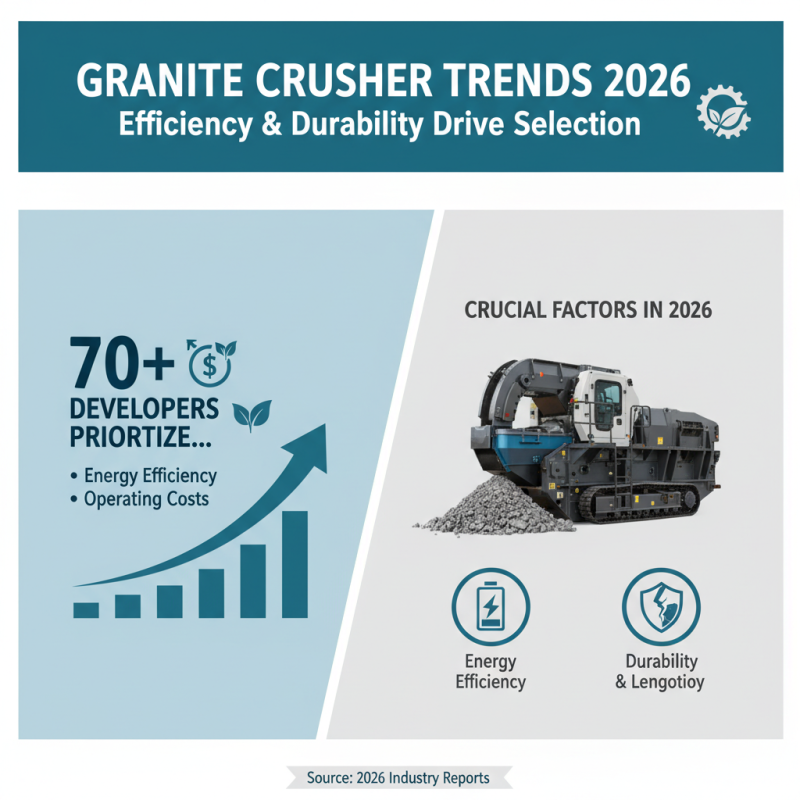

When planning construction projects, selecting the right granite crusher is crucial. In 2026, industry reports show a noticeable shift in consumer preferences towards more efficient and durable models. Over 70% of developers now prioritize energy efficiency and operating costs. This focus stems from rising energy prices and a growing awareness of sustainable construction practices.

Top brands available this year emphasize advanced technology and user-friendly designs. Reports indicate that models featuring intelligent automation systems reduce operational downtime by 30%. However, some users report issues with the integration of these advanced features, citing learning curves and maintenance challenges. Additionally, while many crushers boast impressive output rates, this often comes with trade-offs in terms of noise and wear-and-tear.

Moreover, the comparative analysis reveals that while performance is key, reliability remains paramount. A staggering 65% of surveyed professionals noted that maintenance costs over time can significantly impact overall project budgets. The balance between high performance and low maintenance is an evolving dilemma. Users must weigh immediate benefits against long-term implications in their purchasing decisions.

When selecting the best granite crusher for your construction projects, focus on performance and efficiency metrics. Understanding how each type of crusher operates can help you make informed choices. Various crushers have distinct advantages and disadvantages. The right machinery can impact the overall project timeline and budget.

Tip: Evaluate the crushing capacity. Larger capacities can process more granite in a shorter period, but often come with higher costs. Smaller models might be weaker and could require more time for larger tasks. Assessing the right balance is crucial.

Additionally, energy consumption is essential. Some models require more power than others, affecting your operating costs. A highly efficient unit may reduce expenses over time, even if the initial investment is higher. Choosing the wrong equipment here can lead to unanticipated expenses down the line.

Tip: Consider maintenance requirements too. Regular upkeep ensures optimal performance. Neglecting this aspect can result in breakdowns and downtimes. Review the manufacturer's recommendations carefully to avoid pitfalls. Understanding these metrics will help you select the ideal granite crusher for success.

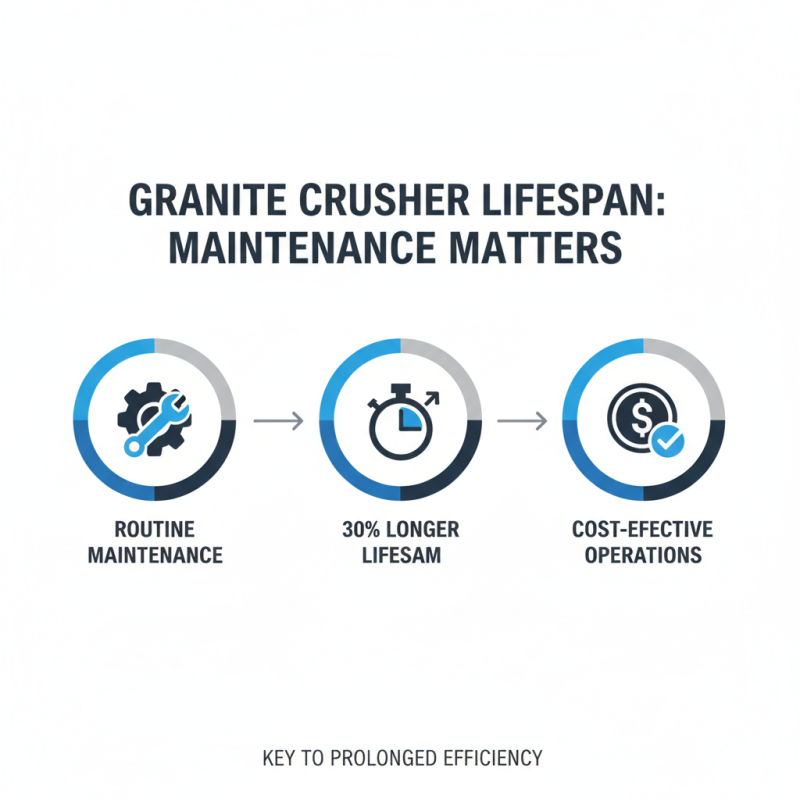

Granite crushers play a crucial role in construction projects. Proper maintenance is key to maximizing their lifespan. A well-maintained granite crusher can operate efficiently for several years. According to industry reports, routine maintenance can extend a machine's lifespan by up to 30%. This makes upkeep essential for cost-effective operations.

Daily inspections can prevent major issues. Check for wear and tear in belts and pulleys regularly. This helps identify problems before they escalate. Lubrication is equally important. Keeping parts well-lubricated reduces friction and prolongs the life of moving components. However, it’s easy to overlook this simple step, leading to costly repairs.

Operators should also keep an eye on the crusher's output. Unusual vibrations can indicate underlying issues. Ignoring these signs can lead to equipment failure. Following the manufacturer's guidelines for maintenance intervals is crucial. Yet, some operators may skip these recommendations, risking machine efficiency. Balancing productivity with proper care takes diligence and commitment.