-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

Limestone crushers play a vital role in various industries. The right equipment can significantly enhance efficiency in crushing operations. According to industry expert John Smith, “Choosing the right limestone crusher is crucial for optimal production.” This emphasizes the importance of selecting suitable machinery.

The market offers numerous options. Each limestone crusher varies in features and effectiveness. Some models excel in high-speed operations. Others prioritize energy efficiency. It’s essential to know your specific needs before making a decision.

However, not all models perform equally well in all conditions. Users must evaluate their operational context. Furthermore, some designs may have limitations that could affect production rates. Understanding these aspects can drastically improve performance and reduce downtime in a project.

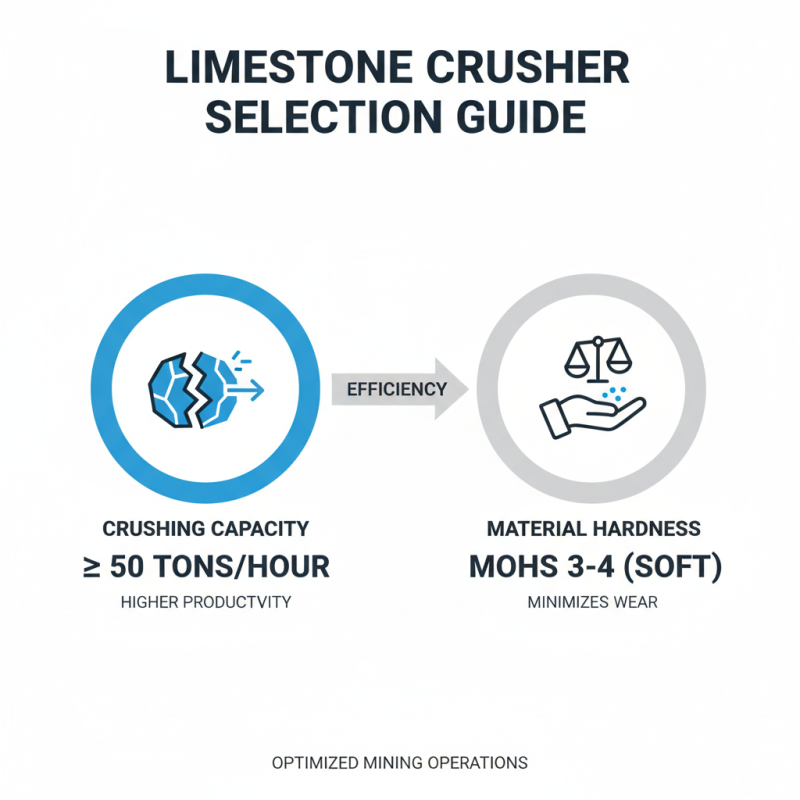

When selecting a limestone crusher, key features greatly impact efficiency. Firstly, consider the crushing capacity. Reports indicate that crushers with a capacity of at least 50 tons per hour often yield better productivity in mining operations. Material hardness is another crucial factor; limestone typically ranges from 3 to 4 on the Mohs scale, suggesting that crushers designed for softer materials can be effective while minimizing wear.

It’s important to evaluate the size and maintenance requirements. Crushers that are easier to maintain tend to have lower operational costs. The best units allow for easy access to key components, reducing downtime. Monitoring systems also play a role; advanced crushers feature real-time data tracking, helping operators adjust settings and prevent unforeseen breakdowns.

**Tips:** Regularly check the crusher's wear parts to ensure optimal performance. Investing in staff training can help maintain efficient operation. Consider your site's specific needs while choosing a crusher. Making hasty decisions can lead to subpar results and additional costs. Always reflect on past choices to improve future equipment selection.

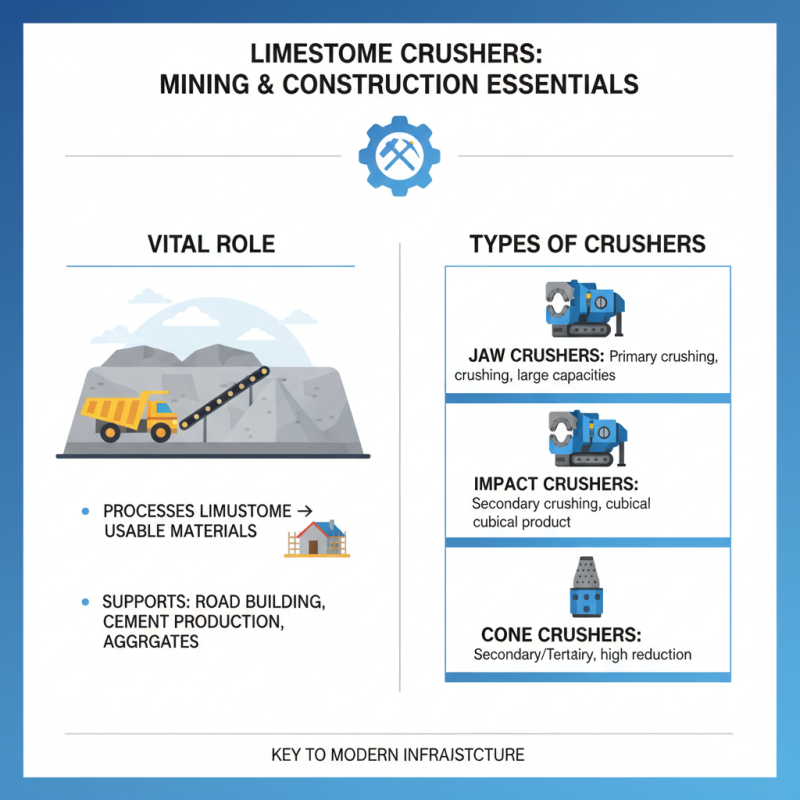

Limestone crushers play a vital role in mining and construction industries. They are essential for processing limestone into usable materials. Different types of limestone crushers are available today, each with distinct features.

Jaw crushers are fundamental. They handle large materials and offer a high crushing ratio. Their durability is noted in various industry reports, showing efficiency levels around 70-85%. Impact crushers, however, focus on softer stones. They produce finer aggregates but wear out quicker. Some studies suggest they may need replacement every 200 to 400 hours of operation.

Cone crushers come next. They crush limestone with precision and can produce uniformly sized stones. The downside? They often require more maintenance. Some users report that their efficiency drops significantly after prolonged use. Lastly, hammer crushers are cost-effective for small operations, but they might not withstand heavy-duty applications. Each option has strengths and weaknesses, making the choice dependent on specific operational needs.

When comparing limestone crushers, efficiency is key. Recent studies indicate that the crushing ratio and energy consumption are critical metrics. For instance, well-designed models can achieve a crushing ratio over 20:1. However, some machines may struggle to reach this efficiency, resulting in wasted energy and increased costs.

Recent performance reports highlight that various crushers tend to operate at different levels of effectiveness. In one analysis, machines that utilize advanced technology showed a 30% reduction in power consumption compared to traditional models. Yet, some units still fail to optimize their output consistently. A specific design flaw can lead to excessive wear and tear, ultimately affecting productivity.

Furthermore, maintenance plays a vital role in operational efficiency. Regular servicing can prolong the life of crushers, reducing downtime significantly. Not all machines are built with easy maintenance in mind. A complex design may hinder operators from performing necessary checks. This raises concerns about long-term dependability and total cost of ownership. Ultimately, choosing the right limestone crusher means weighing these factors carefully. Efficient design, reliable performance, and ease of maintenance are all essential for minimizing operational challenges.

This chart illustrates a comparative analysis of efficiency among popular limestone crushers based on their throughput (tons per hour) and energy consumption (kWh) for optimal crushing operations.

Maintaining limestone crushers is crucial for optimal performance. Regular maintenance checks can prevent costly breakdowns. Inspect the crusher daily for wear and tear. Pay attention to the wear plates. These parts face constant impact and need replacement when worn.

Check the lubrication system regularly. Proper lubrication reduces friction and prolongs equipment life. A well-lubricated machine runs smoother and more efficiently. Neglected lubrication leads to increased wear and unexpected failures.

Operator training is essential too. Ensure all staff know how to operate crushers properly. Mistakes during operation can lead to inefficiencies. A common issue is overloading the crushers. This can cause jams and damage. Keep operators informed about safe loading practices.

Incorporating these tips helps enhance the performance of limestone crushers. Daily vigilance can make a noticeable difference in productivity. Consistent maintenance practices lead to fewer unexpected downtimes. Remember, even small oversights can snowball into larger issues.

| Crusher Type | Max Input Size (mm) | Capacity (ton/h) | Power (kW) | Weight (kg) |

|---|---|---|---|---|

| Jaw Crusher | 600 | 150 | 110 | 4000 |

| Impact Crusher | 500 | 200 | 132 | 3000 |

| Cone Crusher | 450 | 120 | 75 | 3500 |

| Roll Crusher | 300 | 90 | 55 | 2500 |

| Hammer Crusher | 400 | 160 | 200 | 5000 |

| Vertical Shaft Impact Crusher | 350 | 100 | 75 | 4500 |

| Mobile Crusher | 500 | 250 | 170 | 6000 |

| Stationary Crusher | 600 | 300 | 150 | 7000 |

| Grizzly Feeder | 400 | 80 | 40 | 2000 |

| Screening Plant | N/A | 150 | 55 | 3500 |

Limestone crushers play a vital role in various industries. They are essential for construction, agriculture, and even environmental protection. In construction, limestone is crushed into aggregates for concrete and asphalt. According to industry studies, about 1.6 billion tons of crushed stone is produced each year in the U.S alone, with limestone accounting for over 70% of this total.

In agriculture, crushed limestone is used to enhance soil quality. It improves pH levels and adds calcium and magnesium nutrients. The National Lime Association indicates that approximately 26 million tons of agricultural lime is used annually. This highlights its importance in crop production.

Furthermore, limestone crushers are used in environmental applications. They help in treating wastewater and managing pollution. The crushed limestone reacts with impurities, effectively neutralizing acidity. However, the operations must be efficient and environmentally friendly. Not all crushers meet these standards, leading to inefficiencies. It's crucial to explore options that align with sustainable practices.