-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

Choosing the right Jaw Crusher for your crushing needs is a crucial step in enhancing the efficiency and effectiveness of your operations. According to the latest industry reports from the International Journal of Mining and Mineral Engineering, the global market for Jaw Crushers is projected to reach approximately $3 billion by 2026, indicating significant growth driven by the increasing demand for mineral and aggregate processing in construction and mining sectors. This data emphasizes the necessity for businesses to make informed choices when selecting crushing equipment.

Industry expert Dr. Michael Smith, a recognized authority in the field of mining and construction machinery, stresses the importance of matching the Jaw Crusher specifications to the specific application. He states, “Selecting the right Jaw Crusher is not just about capacity; it’s about understanding the material characteristics and production goals.” This perspective reinforces the need for a thorough assessment of crushing requirements, as a well-chosen Jaw Crusher can significantly enhance productivity while reducing operational costs. As such, this article aims to provide valuable insights to help decision-makers navigate the complexities associated with selecting the appropriate Jaw Crusher for their unique needs.

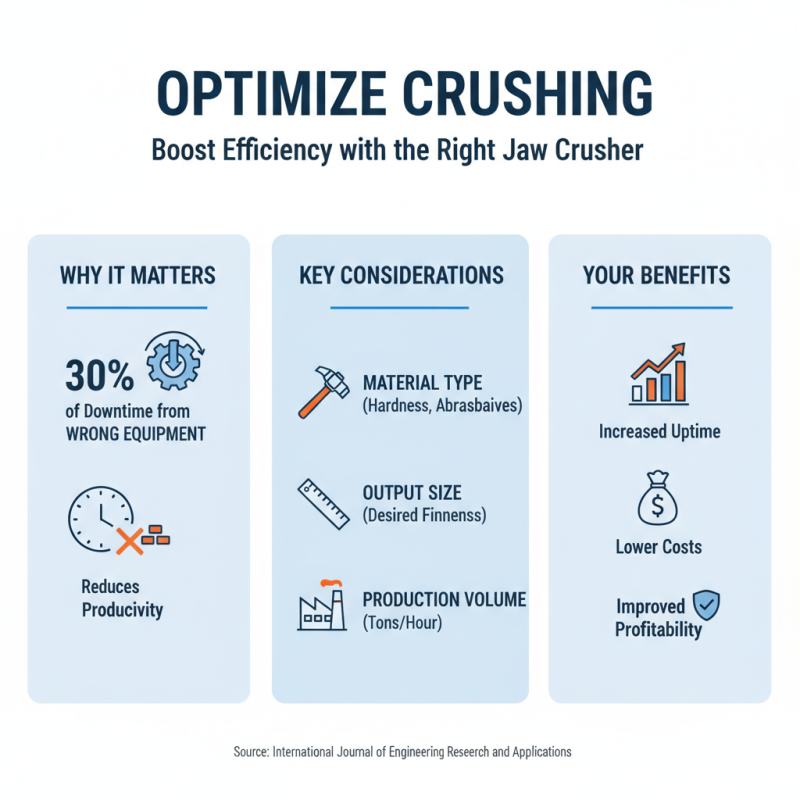

The selection of an appropriate jaw crusher is critical to optimizing operational efficiency and productivity in various industries, including mining, construction, and recycling. According to a report by the International Journal of Engineering Research and Applications, nearly 30% of operational downtime in aggregate production can be attributed to inadequate equipment selection. Therefore, it is essential to understand the specific crushing needs of your operation, including material type, desired output size, and anticipated production volume.

When choosing a jaw crusher, operators must consider factors such as the hardness and abrasiveness of the material being processed. Industry data suggests that harder materials, such as granite or basalt, may require crushers with a larger crushing ratio and a more robust design to withstand increased wear and tear. Furthermore, having a clear understanding of the required throughput can guide the selection process. For instance, studies indicate that a jaw crusher capable of processing 150 tons per hour may be suitable for mid-sized operations, aligning with reported industry benchmarks for cost-effective production rates. Hence, thoroughly evaluating these parameters will lead to a more suitable and efficient crusher, ultimately enhancing productivity while minimizing operational costs.

When selecting the right jaw crusher, several key factors must be taken into consideration to ensure optimal performance tailored to specific crushing needs. The first major consideration is the size and type of material that will be processed. Different models excel with varying degrees of hardness, size distribution, and moisture content in the materials. Therefore, understanding material characteristics is crucial in determining the appropriate jaw crusher model that can effectively handle the expected load without compromising efficiency.

Another important factor is the capacity requirements of your operation. This can involve assessing the volume of material you need to crush on a daily basis, as well as the desired output size. Jaw crushers are available in various sizes and configurations, and it is essential to select a model that not only meets your production goals but also aligns with other equipment in your processing line. Additionally, considerations around power consumption, maintenance needs, and overall project budget will also play a significant role in the decision-making process, ensuring that the chosen jaw crusher aligns with both operational and economic objectives.

When selecting the right jaw crusher for your specific crushing needs, understanding the characteristics of the material being processed is crucial. Different materials exhibit various physical and mechanical properties, such as hardness, abrasiveness, size distribution, and moisture content. These characteristics not only influence the choice of the jaw crusher but also determine the optimal settings for achieving efficient and effective crushing. For instance, harder materials may require a crusher with greater durability and increased jaw strength to withstand the impact and reduce wear, while softer materials might necessitate less aggressive settings.

Moreover, the size and shape of the material significantly affect the jaw crusher's performance. Materials that are chunkier or irregularly shaped may need a design that can accommodate such variability, ensuring that the crusher can operate smoothly without causing blockages. Additionally, understanding the moisture content of the material can guide decisions on screening and separation processes, as high moisture levels can lead to unexpected material handling challenges. Therefore, a thorough analysis of these material characteristics is essential for selecting a jaw crusher that not only meets performance requirements but also enhances operational efficiency.

| Material Type | Hardness (MOH Scale) | Recommended Jaw Crusher Size | Typical Compression Ratio | Feed Size (mm) |

|---|---|---|---|---|

| Granite | 6-7 | 40" x 30" | 6:1 | 300-500 |

| Limestone | 3-4 | 30" x 20" | 8:1 | 150-300 |

| Basalt | 6-8 | 50" x 40" | 7:1 | 250-450 |

| Concrete | 5-6 | 36" x 30" | 10:1 | 200-350 |

| Clay | 2-3 | 24" x 16" | 8:1 | 100-200 |

When selecting the right jaw crusher for your specific crushing needs, one of the most critical factors to consider is throughput. Throughput refers to the volume of material that the crusher can process in a given timeframe. To evaluate this, you must consider the size and type of material being crushed, as well as the desired product size. For instance, if your operation involves larger and denser rocks, you will need a crusher with a higher throughput capability to effectively handle the increased workload without compromising speed or efficiency.

Equally important is understanding the size reduction requirements of your operation. The jaw crusher's design should align with the size specifications of the feed material and the desired end product. Assessing the maximum dimensions and weight of the material will help determine the appropriate jaw size and configuration. Additionally, consider the reduction ratio, which dictates how much size reduction the material will undergo during processing. Ideally, the equipment should facilitate not just throughput but also provide efficient size reduction to ensure optimal performance and minimal wastage in your crushing process.

When selecting a jaw crusher, it is essential to compare the specifications and capabilities of various models to ensure that the chosen machine meets your specific crushing needs. The main considerations include feed size, production capacity, and the type of materials to be crushed. For instance, a crusher designed to handle larger feed sizes will typically require a more robust construction and may have different jaw configurations compared to those meant for smaller materials. Knowing the maximum feed size helps in determining the appropriate model that can efficiently process the required throughput.

Another crucial factor to consider is the crushing ratio, which indicates the size reduction achieved by the crusher. Higher crushing ratios often translate to lower operational costs and greater efficiency in production. Additionally, the strength of the jaw plates and the material used in construction play a vital role in durability and wear resistance, especially in demanding applications. Evaluating these specifications will help users not only in maximizing productivity but also in minimizing downtime and maintenance costs, ultimately leading to a more effective crushing operation.