-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

In the construction industry, the selection of the right machinery is crucial for optimizing efficiency and ensuring quality outcomes. One such vital component is the Limestone Crusher, a machine specifically designed for processing limestone—a sedimentary rock that is a key ingredient in various construction materials like cement, concrete, and asphalt. According to a report by Grand View Research, the global limestone market is projected to reach approximately $84 billion by 2025, indicating a growing demand for limestone-derived products and, consequently, an increased need for effective limestone crushing solutions.

When considering a Limestone Crusher, it is essential to assess the specific requirements of your project, including production capacity, size reduction ratio, and the desired final product's specifications. The right crusher can significantly impact operational costs and efficiency. The National Stone, Sand & Gravel Association notes that crushers account for about 80% of the total energy consumed in processing; thus, selecting an energy-efficient model can lead to substantial savings over time. This overview emphasizes the importance of understanding various options and selecting a Limestone Crusher that aligns with both the operational needs and the sustainability goals of your construction endeavors.

Limestone is a versatile sedimentary rock composed primarily of calcium carbonate. Its unique properties make it a valuable material in the construction industry. Widely used as an aggregate for concrete and asphalt, limestone contributes to the strength and durability of various structures. Additionally, it serves as a key component in the production of lime, which is essential for processes such as soil stabilization and water treatment. Understanding the characteristics of limestone is crucial for determining its appropriate applications in construction projects.

In construction, limestone finds its uses in different forms. Crushed limestone is often employed as a base material for roads, railways, and foundations, where it provides stability and supports heavy loads. Natural limestone blocks and slabs are utilized for aesthetic purposes in architecture, creating visually appealing walls, floors, and landscaping features. Furthermore, the material’s ability to absorb sound makes it a favorable option for soundproofing in buildings. By taking into account limestone’s attributes and applications, construction professionals can make informed decisions regarding the selection and use of this invaluable resource.

When selecting a limestone crusher, understanding the different types available is crucial for meeting specific construction needs. The market offers several varieties, each designed for distinct applications. Primary crushers, like jaw and cone crushers, are essential for the initial stages of crushing. They are capable of handling large boulders and breaking them down into manageable sizes for further processing. According to the U.S. Geological Survey, the primary sector of the crushed stone industry accounts for nearly 70% of the overall production, highlighting the vital role of these crushers in the supply chain.

In addition to primary crushers, secondary and tertiary crushers, such as impact and hammer crushers, are indispensable for achieving finer material granularity. Impact crushers excel at creating smaller particles, which are essential for applications requiring high grading standards. Industry reports estimate that the global market for impact crushers is expected to grow by approximately 4.5% annually over the next five years, driven by increased construction activities worldwide. These machines utilize strike-and-impact design, making them particularly effective for limestone, which is characterized by its abrasive nature.

The choice between these types largely depends on the scale of your project and desired material specifications. It is crucial to assess the production capacity, feed size, and expected output size when determining the right limestone crusher for your construction needs. Understanding the nuances of each type allows for optimized performance and efficiency, ultimately leading to significant cost savings and enhanced project outcomes.

| Type of Limestone Crusher | Description | Advantages | Disadvantages | Best Use Case |

|---|---|---|---|---|

| Jaw Crusher | Uses compressive force to break down materials. | Efficient at primary crushing; high throughput. | Can be less effective for very hard materials. | Large scale primary crushing projects. |

| Impact Crusher | Breaks down materials with rapid impacts. | Good for softer materials; produces a uniform product. | Not ideal for very hard materials. | Secondary and tertiary crushing. |

| Cone Crusher | Utilizes a rotating cone to crush materials into smaller pieces. | Good for hard materials; produces a consistent product size. | More complex maintenance and potentially higher costs. | Mining and aggregate industries. |

| Hammer Crusher | Uses high-speed rotating hammer to crush materials. | Simple design and operation; lower investment. | Less efficient for larger stones; high wear on parts. | Cement and lime production. |

| Roll Crusher | Crushes materials between two rotating rolls. | Produces minimal fines; great for sticky materials. | Lower efficiency compared to other crushers on harder materials. | Coal and minerals processing. |

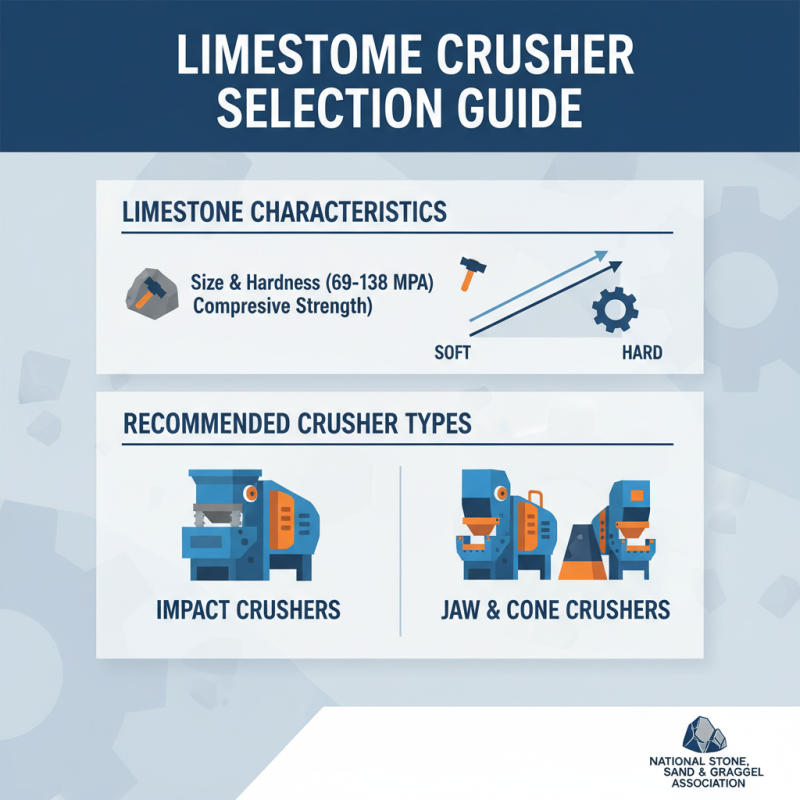

When selecting a limestone crusher for your construction needs, there are several key factors to consider. First and foremost is the size and hardness of the limestone to be processed. According to a report by the National Stone, Sand & Gravel Association, the compressive strength of limestone typically ranges from 69 to 138 MPa, which affects the type of crusher best suited for the task. For softer varieties, impact crushers may suffice, while for harder, denser types, cone crushers or jaw crushers may be more effective to ensure optimal fragmentation and reduction.

Another important consideration is the desired output size and capacity. The production requirements will determine whether a fixed or mobile crusher is more appropriate. Industry data indicates that mobile crushers can provide flexibility on job sites and often improve overall efficiency by reducing transportation costs. Additionally, it's essential to evaluate the crusher’s efficiency rating and energy consumption—an efficient crusher should not only maximize output but also minimize operational costs. According to a report from the U.S. Geological Survey, the limestone production reached over 100 million metric tons in 2020, emphasizing the need for high-efficiency equipment to handle large-scale operations effectively.

When assessing the cost-effectiveness of different limestone crushers, several factors come into play that can significantly impact your overall investment. The initial purchase price is just the starting point; one must also consider operating costs, including maintenance, energy consumption, and replacement parts. Evaluating the total cost of ownership can provide a more accurate picture of how a particular model will perform over its lifespan. Choosing a more efficient machine may have a higher upfront cost but could result in lower long-term expenses, making it a smarter investment.

Additionally, the production capacity and material suitability of various crusher models must be taken into account. A machine that can handle a larger volume of materials efficiently might be more cost-effective, even if its per-unit processing cost seems higher. Understanding the specific requirements of your construction project, such as the type of limestone and the desired output size, will help in making an informed decision. Comparing features such as power ratings, throughput capacity, and durability will allow construction managers to select a crusher that aligns with both operational needs and budget constraints.

When selecting a limestone crusher for construction needs, maintenance and durability are critical factors that greatly influence operational efficiency and long-term cost-effectiveness. According to industry findings, regular maintenance can extend the lifespan of a crusher by up to 30%. Key aspects to consider include the frequency of wear part replacements and the ease of accessing internal components for service. For example, crushers designed with easy-access hatches allow for quicker inspections and replacements, thus minimizing downtime significantly.

Durability in limestone crushers is also closely tied to the materials used in their construction. High-quality steel and advanced composites frequently withstand the abrasive nature of limestone much better than standard materials. Reports indicate that using premium materials can enhance resistance to wear and tear by up to 40%, resulting in lower repair costs and longer intervals between necessary maintenance. Moreover, consistent monitoring of the machine’s performance, through vibration analysis or thermal imaging, helps in identifying potential issues early on, thereby preventing costly breakdowns and ensuring continuous operation on construction sites.