-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

Choosing the right Jaw Crusher Machine is essential for project success. The global mining equipment market is projected to reach $202.4 billion by 2027, indicating a robust demand for efficient crushing machinery. Jaw crushers account for a significant portion of this market due to their versatile applications in mining, construction, and recycling.

A well-selected Jaw Crusher Machine can optimize productivity and reduce operational costs. However, many projects fail to achieve desired outcomes due to poor equipment choices. Factors such as material type, crushing capacity, and site conditions are critical in this decision. Misjudging these aspects can lead to increased downtime and maintenance costs.

Investing in the right jaw crusher is crucial. Research shows that improper equipment can cause efficiency losses of up to 30%. It's important to analyze your project requirements carefully. Selecting a machine that doesn't fit your needs may result in poor performance. Explore various options thoroughly to ensure the best fit for your specific project context.

Selecting the right jaw crusher is crucial for project success. Understanding the types available helps in making an informed choice. There are primarily two categories: traditional and modern jaw crushers. Traditional models often lack efficiency compared to newer alternatives. A recent industry report indicates that modern crushers can enhance productivity by up to 30%.

When analyzing jaw crushers, consider their design features. Single-toggle and double-toggle jaw crushers serve different needs. A double-toggle design typically handles tougher materials and offers better throughput. However, they may be more complex and require more maintenance. It’s essential to assess the material type and desired output.

Another important factor is sizing. The physical dimensions directly impact the feed capacity and energy consumption. A smaller jaw crusher may suit limited spaces but can compromise output. Meanwhile, larger models might lead to higher operational costs. Balancing size and efficiency is not an easy task. Erring on either side could affect performance in the long run. Examining operational requirements closely is necessary to avoid costly mistakes.

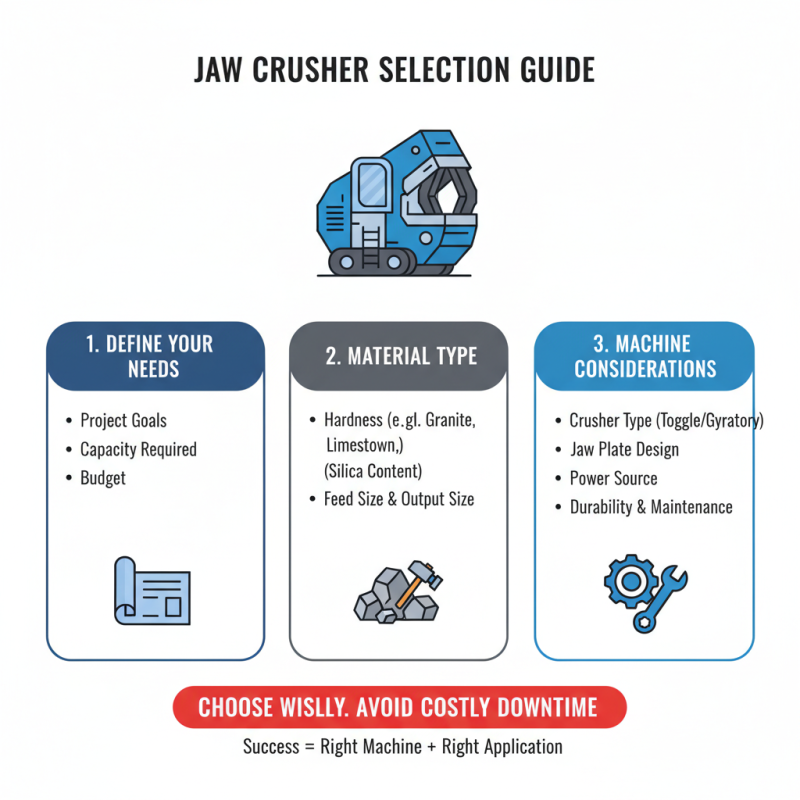

Choosing the right jaw crusher machine is crucial for project success. Understand your specific needs before making a decision. Consider the material type you'll process. Different materials exert various forces on the machine. Harder materials require stronger machines to avoid quick wear and tear. If you overlook this, you may face higher maintenance costs later.

Capacity is another key factor. How much material do you need to crush daily? Assess your project scale. A machine that is too small will lead to inefficiencies. Conversely, an oversized machine may be unnecessary and costly. Analyze your production goals and match them with the machine's output.

Always evaluate portability and space. Will the machine fit in your work area? Some projects demand mobility, while others can accommodate larger fixed machines. Remember to reflect on your project’s timeline and budget as well. Sometimes, cheaper options may compromise quality, leading to future headaches. Finding the right balance is essential for long-term success.

Selecting the right jaw crusher for your project begins with understanding your material requirements. Different materials have unique properties. Hard rock, for instance, demands a robust machine. Softer materials might not need such heavy-duty equipment. Analyze the hardness, size, and shape of the material you're dealing with. This will guide your choice effectively.

Consider the capacity you need. Will your project require continuous operation? If so, choose a model that can handle the volume. A machine with insufficient capacity could result in delays. Also, think about the material's moisture content. Wet materials can behave unpredictably in a crusher. Adjustments may be necessary to ensure efficient crushing.

Don’t forget about your project's budget. Cheaper machines may seem appealing, but they can incur higher costs later. Maintenance, efficiency, and durability matter. Balancing initial investment and long-term benefits is key. Take the time to reflect on these aspects. It can save you from potential regrets down the line. Make informed decisions, but be prepared to adapt your choices as the project evolves.

| Material Type | Hardness Level (Mohs) | Recommended Crusher Type | Typical Feed Size (mm) | Output Size (mm) |

|---|---|---|---|---|

| Granite | 6-7 | Jaw Crusher | 250-600 | 20-100 |

| Limestone | 3-4 | Jaw Crusher | 200-500 | 10-50 |

| Basalt | 5-6 | Jaw Crusher | 300-700 | 20-80 |

| Sandstone | 6-7 | Jaw Crusher | 150-400 | 5-40 |

| Clay | 1-2 | Impact Crusher | 100-300 | 0-30 |

When choosing a jaw crusher for your project, assessing the required capacity and size is crucial. The size of the raw material directly influences the type of jaw crusher needed. For instance, a larger feed requires a larger opening. According to a recent market analysis, jaw crushers with a capacity between 50-100 tons per hour are ideal for mid-size projects. This data indicates that a crusher with a production capacity below 50 tons may not meet your project's needs.

The output size is another significant factor. Most projects require a specific particle size distribution. Studies show that a jaw crusher can typically produce output sizes ranging from 10mm to 100mm. Yet, achieving the desired size can be challenging. Redistributing material or adjusting the settings may not suffice. There may be a learning curve in understanding how to adjust for different material types, hardness, and desired sizes.

In practice, not all machines will perform identically under similar conditions. Variability in feed material can lead to unexpected output sizes. Hence, testing must be part of your selection process. Oversights in assessing size and capacity can lead to inefficiencies. Understanding your material characteristics is vital for selecting the right machine. This attention to detail may determine the success of your project.

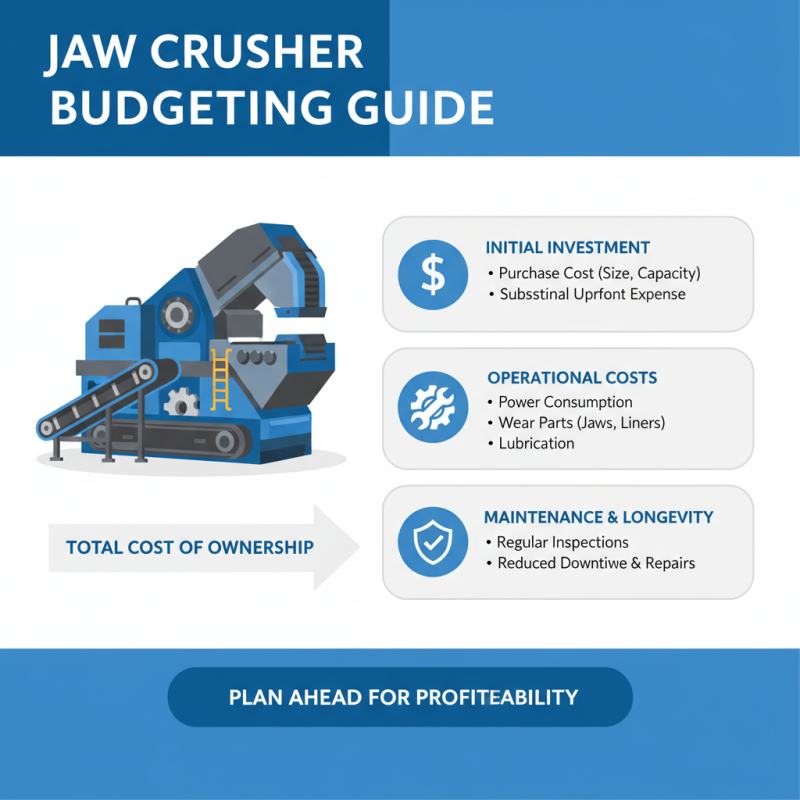

When budgeting for a jaw crusher machine, consider both the purchase cost and ongoing maintenance expenses. The initial investment can be substantial, depending on the machine’s size and capacity. It’s crucial to plan for operational costs as well. Regular maintenance can prevent costly repairs and downtime.

Tips to remember: always account for spare parts in your budget. Unexpected repairs can arise. Set aside a fund for these emergencies. Additionally, consider the availability of service providers to handle repairs. Proximity can significantly reduce repair times.

Also, think about the energy consumption of the jaw crusher. A machine that consumes more energy will increase operational costs. Evaluating the energy efficiency of potential models can lead to significant long-term savings. Weigh the benefits of reliable machines against their costs. Sometimes, cheaper machines lead to higher long-term expenses. Do the math carefully to avoid future budgeting issues.