-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

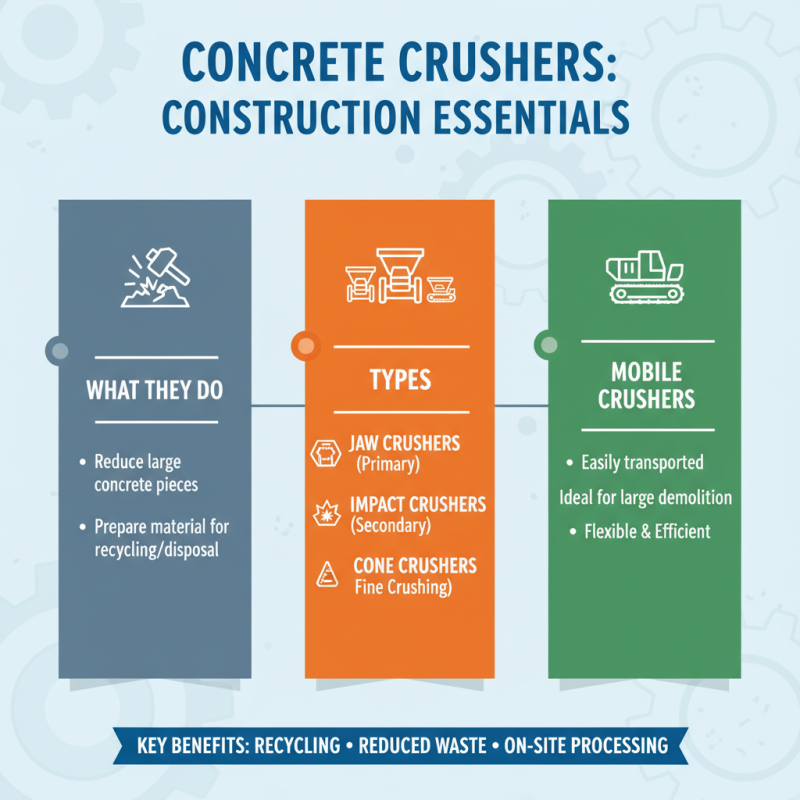

Concrete crushers are essential tools in the construction and demolition industries. They facilitate the rapid breakdown of concrete structures, making recycling feasible. Various types of concrete crushers exist, each tailored for specific applications and environments.

Understanding the different concrete crushers can help optimize the demolition process. For instance, mobile crushers are versatile and can be used on-site. Stationary crushers, on the other hand, are perfect for larger projects. Each type has unique features that cater to different needs.

However, choosing the right concrete crusher is not always straightforward. Each project has distinct challenges; project managers must assess size, mobility, and output. Misjudgment can lead to inefficiencies or increased costs. Reflecting on one’s choices is crucial in maximizing the benefits of these powerful machines.

Concrete crushers are essential in the construction and demolition industries. They come in different types, each suited for specific tasks. Mobile crushers are quite popular. They can be easily transported to various job sites. This flexibility makes them ideal for large-scale demolition projects.

Fixed crushers are another option. They are typically used in facilities where large volumes of concrete need to be processed. These machines are robust and can handle heavy loads. Meanwhile, jaw crushers are efficient for breaking down large blocks. Their design allows for thorough crushing, but they can be less effective with rebar.

Impact crushers operate differently. They use high-speed impacts to break concrete, which can be beneficial for recycling materials. However, they may not provide the same level of control as jaw models. Choosing the right type of concrete crusher requires careful consideration. Each option has its strengths and weaknesses. Understanding the specific needs of a project is crucial. Well-informed choices lead to better results.

Primary concrete crushers are essential in construction and demolition projects. They are designed to handle heavy-duty tasks. These crushers break down large concrete structures into manageable pieces. Common types include jaw crushers and impact crushers. Each has unique characteristics suited for different applications.

Jaw crushers are effective for primary crushing. They offer a high level of efficiency and can crush large pieces of concrete. However, they may not perform well on very hard materials.

Impact crushers, on the other hand, excel when it comes to speed. They can break down concrete quickly, making them suitable for recycling applications. Yet, they might struggle with very thick concrete.

Tips: Always assess the size and type of concrete before choosing a crusher. Selecting the wrong type can lead to inefficiencies. Regular maintenance is also crucial. Neglecting this can result in unexpected downtime and higher costs. Be aware that not all machines are versatile. Some models might perform exceptionally well in one aspect and poorly in another.

Secondary and tertiary concrete crushers play a crucial role in the recycling process. They are designed to crush concrete materials after primary crushing. This step helps to reduce the size of the materials, making them suitable for various applications. A report by Grand View Research indicates that the global construction waste recycling market is expected to reach USD 66.4 billion by 2027, highlighting the demand for efficient concrete crushing solutions.

Secondary crushers, often used in conjunction with primary crushers, provide a finer crushing outcome. They ensure that the output material meets specific size requirements for reuse. This is important for maintaining quality in construction projects. Tertiary crushers, on the other hand, focus on achieving an even finer product. Reports suggest that up to 75% of crushed material can be re-used in new construction, making these crushers essential for sustainable building practices.

Despite their importance, many operators overlook the differences between these two types. This can lead to inefficiencies in the crushing process. For example, using a secondary crusher instead of a tertiary one may result in larger aggregates, which are unsuitable for high-quality projects. Understanding these distinctions is vital for optimizing operations and promoting effective recycling within the construction industry.

Concrete crushers play a pivotal role in recycling and demolition projects. They efficiently break down concrete structures into manageable pieces for reuse. Data from the National Recycling Coalition reveals that recycling construction materials can minimize waste by up to 65%. This process not only conserves resources but also reduces landfill usage.

In demolition, the use of concrete crushers aligns with sustainability goals. A report by the Environmental Protection Agency states that recycling concrete can save about 1,200 pounds of water per ton. However, not all projects realize these benefits. Some sites still overlook the importance of using appropriate crusher types. Small crushers may not handle large debris effectively, leading to delays.

Furthermore, choosing the right type of crusher is crucial. Jaw crushers provide powerful crushing, while impact crushers excel in speed. But there are issues. Operators may not always know which type to use. This misstep can waste time and resources. Equipment selection should be a deliberate process. Each project needs careful consideration of its specific requirements to optimize efficiency.

Concrete crushers have a significant industrial impact on construction efficiency and costs. A study by the National Association of Waste and Recycling Industry reveals that using concrete crushers can reduce costs by up to 30%. This reduction primarily stems from decreased transportation fees and landfill expenses. By reusing crushed concrete as aggregate, companies can save money and support sustainable practices.

Moreover, concrete recycling enhances project efficiency. Projects that employ concrete crushers can see time savings of about 25%. This data from industry reports suggests that jobs complete quicker when waste material is processed on-site. However, this approach is not without challenges. Mismanagement of equipment can lead to delays. Additionally, not all materials may be suitable for recycling. It is important to evaluate the quality of concrete being crushed, as contaminants can affect the final product.

While the benefits are clear, companies must also weigh potential downsides. There may be initial costs associated with acquiring or renting concrete crushers. Furthermore, worker training is essential for effective operation. Without proper training, accidents can happen. This highlights the need for a balanced approach in adopting concrete crushers for construction projects.

| Crusher Type | Features | Applications | Cost Impact | Construction Efficiency |

|---|---|---|---|---|

| Jaw Crusher | High compressive strength, efficient size reduction | Primary crushing, recycling of concrete | Moderate initial investment, low operating costs | High, ideal for large-scale projects |

| Cone Crusher | Versatile, produces uniform material | Secondary and tertiary crushing, hard materials | Higher maintenance cost, long lifespan | Very efficient for fine material |

| Impact Crusher | Quick material size reduction, less energy | Concrete recycling, aggregate production | Moderate costs with efficient operation | High, quick processing speeds |

| Hammer Mill Crusher | High speed, effective for softer materials | Material pulverization, preparation for recycling | Lower cost but higher energy consumption | Efficient for smaller scale operations |