-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

Concrete Jaw Crushers have become essential in modern construction. They offer powerful solutions for breaking down large materials. According to industry expert Michael Turner, "A Concrete Jaw Crusher is vital for efficient material handling on construction sites."

The design of Concrete Jaw Crushers allows for versatility. They can process various materials and adapt to different site conditions. This flexibility makes them a top choice for contractors.

However, their benefits come with challenges. Maintenance of a Concrete Jaw Crusher demands attention. Proper training for operators is crucial to prevent accidents. Quality monitoring of output is necessary to ensure reliability. Overall, while Concrete Jaw Crushers are invaluable, their operation requires diligence and care.

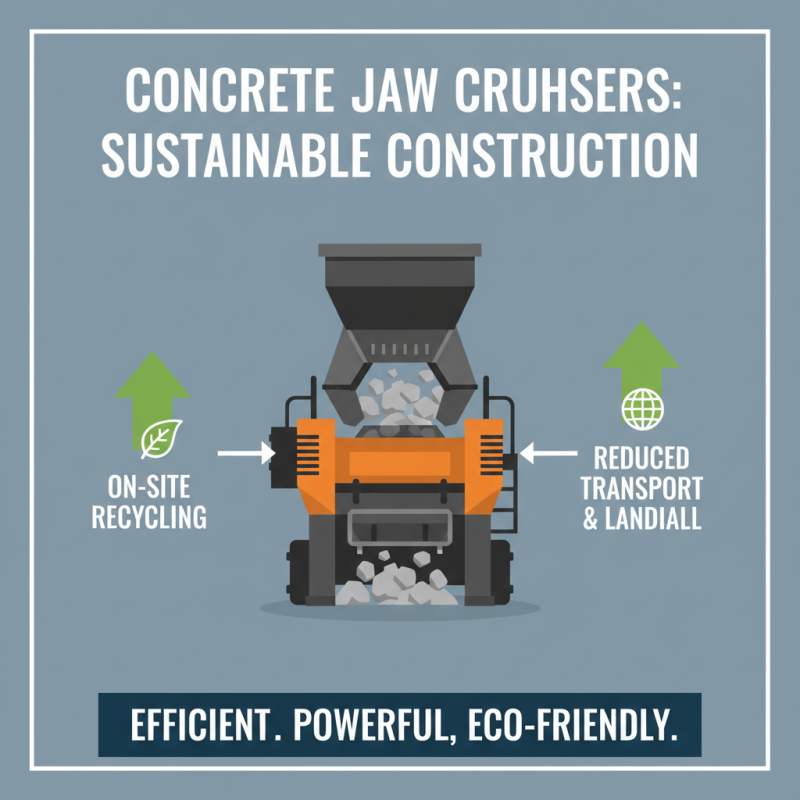

Concrete jaw crushers have become essential in modern construction. These machines excel in crushing hard materials like concrete, brick, and stone. Their power helps in site preparation, recycling, and demolition projects. The ability to crush concrete on-site minimizes the need for transport and landfill. This leads to a more sustainable construction process.

Using concrete jaw crushers can speed up project timelines. They allow contractors to process materials quickly and efficiently. However, operators must be trained to handle these machines safely. Poor handling can lead to accidents or equipment damage. Regular inspections and maintenance are also crucial to ensure optimal performance and safety.

Tips: Always wear protective gear when operating machinery. Train your team thoroughly. It’s essential for safety and efficiency. Evaluate the crusher's performance regularly. If it’s not meeting expectations, it may need adjustments or replacement. Adapting to these insights can enhance your project outcomes significantly.

Concrete jaw crushers are essential in modern construction. Their

compact design and powerful performance make them ideal for breaking down large concrete structures. These machines have

notable features that enhance efficiency and operational effectiveness. For instance, their robust crushing jaws can

process a range of materials, from bricks to reinforced concrete.

The hydraulic system in many concrete jaw crushers allows for precise control.

Operators can adjust the crushing force to accommodate various project requirements. This adaptability is crucial

when dealing with different types of materials. Additionally, the strong frame and

durable parts ensure extended service life. However, regular maintenance is necessary to avoid potential issues,

such as wear and tear.

Another key feature is the mobility of these machines. Many models can be transported to various job sites

with ease. This portability saves time and resources during projects. Yet,

this can lead to oversights in site setup if not planned well. Operators must remember to assess the working

environment to maximize the effectiveness of their equipment.

Concrete jaw crushers play a crucial role in various construction projects. They are commonly used for recycling concrete. The machines break down large pieces into manageable sizes. This process is vital for creating new building materials. Construction sites generate significant waste. Having a concrete jaw crusher onsite can minimize this waste.

These crushers are effective in road construction. They help in demolishing old structures. The crushed concrete can then be reused as aggregate for new roads. Another application is in bridge repairs. The equipment ensures the rapid removal of damaged concrete. This leads to faster project completion.

However, there are some challenges. Not all concrete can be recycled easily. The presence of steel rebar can complicate matters. Additionally, operators must be trained to use this equipment correctly. Mistakes can lead to accidents or inefficient processes. Regular maintenance is essential too, as wear and tear can affect performance.

Concrete jaw crushers play a significant role in construction. They offer unique advantages compared to other crushing equipment. For instance, they effectively break down hard materials like concrete and stone. This capability makes them ideal for demolition projects. Their design allows for high crushing efficiency and reduced downtime during tasks.

When comparing concrete jaw crushers to impact crushers, several distinctions emerge. Jaw crushers excel in producing a more uniform product size. They handle larger blocks with ease. On the other hand, impact crushers are better for shaping materials and producing finer outputs. However, this often comes at the cost of speed.

Tips:

Regular maintenance is crucial for enhancing concrete jaw crusher performance. Check the wear parts often. This includes jaw plates and liners. If these components wear out, they can affect crushing efficiency. An operator should replace them promptly to avoid costly downtime. Keeping an eye on such details can be the difference between smooth operation and unexpected failures.

Proper lubrication is another key factor. Insufficient grease can lead to overheating. It can also cause parts to wear faster. Ensuring the bearings are well-lubricated can increase the lifespan of a crusher. Regularly inspect fluid levels, and look for leaks.

Finally, a clean machine operates better. Accumulated dust and debris can impact performance. Set a routine for cleaning, especially after heavy usage. Remember, a small oversight can lead to bigger issues down the line. Make time for maintenance, and always stay vigilant.

This bar chart presents the efficiency analysis of a concrete jaw crusher, showcasing power consumption, output per hour, and maintenance frequency. By monitoring these metrics, one can enhance the performance and longevity of the equipment.