-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

When it comes to mining and construction, the efficiency of rock crushing equipment is paramount, and one of the most sought-after machines in this category is the Granite Crusher Machine. These machines play a crucial role in transforming large granite stones into usable aggregates for various applications, including road construction, building foundations, and decorative landscaping. However, with a plethora of options available in the market, selecting the right granite crusher machine can be a daunting task.

In this article, we will guide you through the top 10 granite crusher machines, highlighting their key features and functionalities. Understanding the capabilities of different models will enable you to make an informed decision that aligns with your specific requirements. Furthermore, our comprehensive buying guide will equip you with essential insights into what to look for when investing in a granite crusher machine, ensuring you choose a product that delivers optimal performance and durability. Join us as we explore the essential aspects that will help you navigate the world of granite crushing machinery effectively.

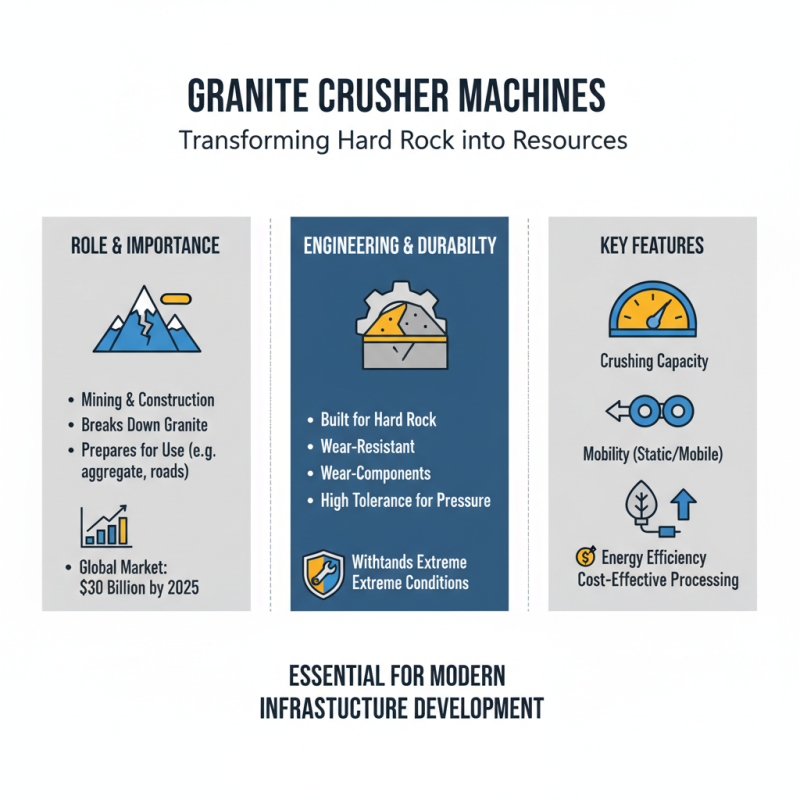

Granite crusher machines play a critical role in the mining and construction industries, primarily used for breaking down granite into manageable pieces for various applications. These machines are engineered to withstand the challenges posed by hard rock materials. According to industry reports, the global granite market is expected to reach $30 billion by 2025, escalating the necessity for efficient stone processing solutions. The effectiveness of granite crushers is determined by several key features, including their crushing capacity, mobility, and energy efficiency.

The market for granite crushers is diverse, with options ranging from stationary systems to portable versions, catering to different operational needs. A pivotal aspect of these machines is their crushing force, which can range from 50 tons per hour to over 1,000 tons per hour, depending on the model. Additionally, advancements in technology have led to the development of eco-friendly crushers that minimize operational emissions, tapping into the growing trend of sustainability within the construction sector. Moreover, a study by Technavio indicates that the granite crusher market is projected to grow at a compound annual growth rate (CAGR) of over 5% between 2021 and 2025, reflecting heightened investments in infrastructural development and mining activities worldwide.

When selecting a granite crusher machine, understanding the key features is essential to ensure optimal performance and durability. One of the primary aspects to consider is the machine's crushing capacity. A higher capacity allows for the processing of larger volumes of granite, making the operation more efficient. Additionally, the size and type of the crushing chamber play a significant role in the machine's effectiveness; a well-designed chamber can efficiently break down granite into desired sizes while minimizing waste.

Another important feature to look for is the machine's mobility. For projects involving multiple locations, portable crushers can save time and labor costs. Furthermore, examining the power source and energy efficiency of the crusher is crucial. Electric-powered models tend to have lower operating costs and are often quieter, while diesel options might offer more power for heavy-duty tasks. Lastly, consider the ease of maintenance and availability of spare parts, as these factors contribute to the longevity and operational reliability of the equipment.

When it comes to choosing the right granite crusher machine, it’s essential to consider various features that can significantly impact performance and efficiency. These machines typically come equipped with powerful engines, sharp crushing jaws, and advanced hydraulic systems to ensure high productivity and durability. Some of the key features to look for include adjustable crushing sizes, ease of maintenance, and the ability to handle various types of granite, which can vary in hardness and density.

The most efficient granite crushers also incorporate noise reduction technologies and dust suppression systems to enhance the working environment.

In our review of the top granite crusher machines, we analyzed their performance across various parameters such as crushing capacity, operational costs, and user-friendliness. Many of the models stand out for their innovative designs that not only ensure effective crushing but also ease of transport and setup.

Key metrics like maintenance frequency and service availability are also crucial when evaluating these machines. Overall, understanding these aspects will help potential buyers make an informed decision, ensuring they select a granite crusher machine that aligns with their specific needs and operational demands.

When considering the purchase of a granite crusher machine, several essential factors come into play to ensure that you choose the right equipment for your needs. First and foremost, examine the machine's processing capacity, which is often measured in tons per hour. This metric is crucial as it determines how much material you can crush in a given timeframe, directly impacting your productivity. Additionally, look for machines with adjustable settings, allowing you to control the size of the output material for various applications.

Another critical aspect to consider is the durability and construction quality of the granite crusher. Machines made from high-grade materials tend to withstand the rigors of heavy-duty use, reducing the frequency of repairs and maintenance. Moreover, evaluate the machine's efficiency in energy consumption; more efficient models can lead to significant cost savings over time. Lastly, always review the available warranties and customer support services, as these can provide peace of mind regarding your investment and assist you in troubleshooting any potential issues after purchase.

To ensure optimal performance and longevity of granite crusher machines, proper maintenance is essential. Regular inspections and routine maintenance can significantly enhance the operational efficiency of these machines. According to industry reports, a well-maintained granite crusher can improve its productivity by up to 25%. Key maintenance aspects include checking the wear parts, such as blow bars and crushing chambers, which can wear down over time due to the abrasive nature of granite.

Lubrication is another critical factor. Maintaining the appropriate lubricant levels can reduce friction and overheating, prolonging the life of the crusher. A study from a leading machinery maintenance journal indicates that inadequate lubrication can lead to a 30% increase in mechanical failures. Furthermore, keeping the machine clean from dust and debris not only improves performance but also minimizes the risk of breakdowns.

Operators should also keep track of the operating hours and follow the manufacturer's recommendations for service intervals. According to the Machinery Institute, regular maintenance checks can lead to a 40% decrease in repair costs over time. By implementing these maintenance strategies, users can optimize the performance of their granite crushers and ensure sustained productivity in their operations.

| Model | Crushing Capacity (tons/hour) | Power (kW) | Weight (kg) | Key Features |

|---|---|---|---|---|

| Model A | 150 | 55 | 8000 | High efficiency, compact design |

| Model B | 200 | 75 | 9000 | Durable, low noise |

| Model C | 250 | 90 | 10000 | High throughput, energy saving |

| Model D | 300 | 110 | 12000 | Automatic feeder, high quality output |

| Model E | 180 | 65 | 7500 | Robust construction, easy maintenance |

| Model F | 220 | 85 | 9500 | Variable speed, precision adjustable |

| Model G | 260 | 95 | 11000 | User-friendly interface, advanced technology |

| Model H | 300 | 100 | 11500 | Low operational cost, versatile use |

| Model I | 240 | 80 | 10200 | Portable model, effective crushing |

| Model J | 195 | 70 | 8000 | Compact and efficient, easy to handle |