-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

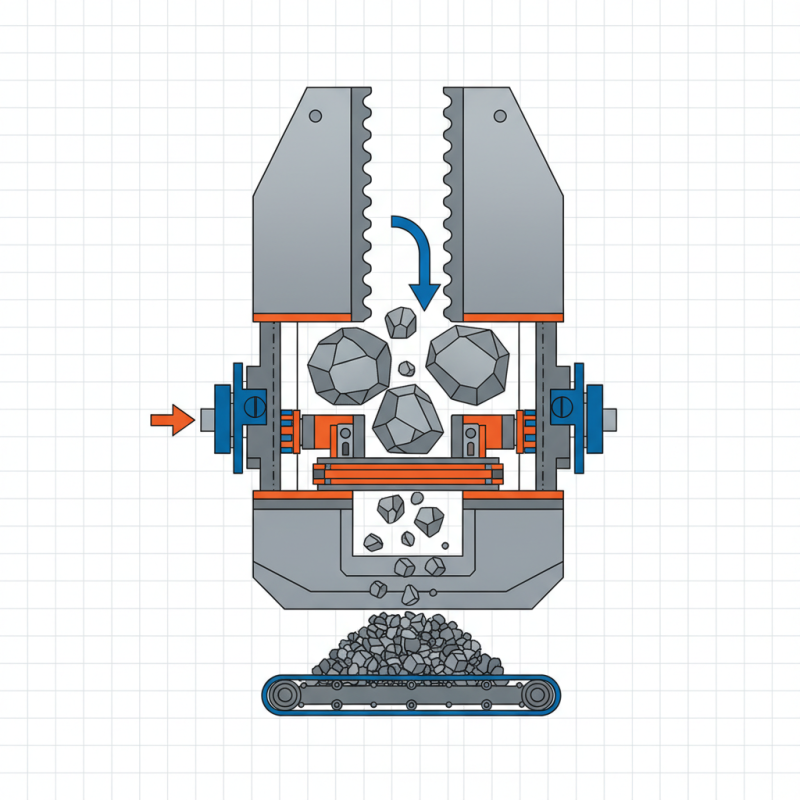

A Jaw Crusher is an essential machine in the mining and construction industries. It efficiently reduces the size of rocks and ores, making them suitable for further processing. The design of this equipment is straightforward yet effective. With two plates, known as the jaw plates, it crushes material through compressive force.

Understanding how a Jaw Crusher works is vital for performing maintenance and ensuring optimal performance. The crushing process involves a stationary and a moving plate. As the moving plate approaches the stationary plate, rocks are squeezed and crushed. This simple action masks some complexities, like wear and tear on the jaw plates. Regular inspection is required.

Notably, the efficiency of a Jaw Crusher can fluctuate based on factors like material hardness and size. Users often overlook these aspects, impacting productivity. Knowing what a Jaw Crusher is and how it functions is crucial for industry professionals. It helps in making informed decisions regarding equipment use and maintenance.

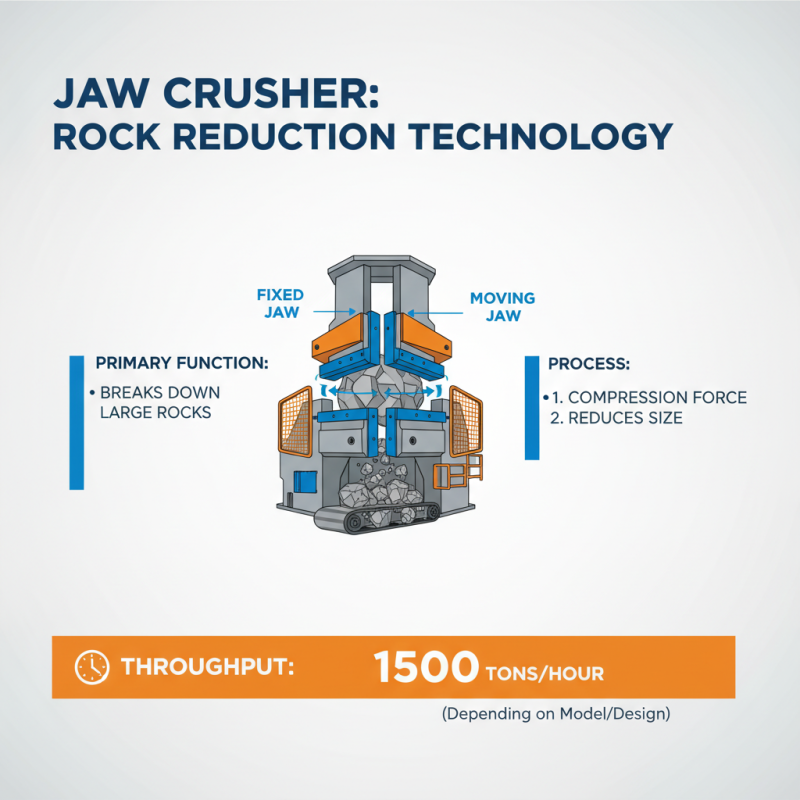

A jaw crusher is a robust machine used in various industries for breaking down rocks and materials. Its primary function is to reduce large stones into smaller, manageable pieces. The process involves a fixed jaw and a moving jaw, which create a compressive force. This force crushes the material, allowing for efficient processing. According to industry reports, jaw crushers can achieve a throughput of up to 1,500 tons per hour, depending on the model and design.

The key components of a jaw crusher include the toggle plate, eccentric shaft, and pits. These parts work together to create a powerful crushing action. The design can vary, but the functionality remains similar across models. Interestingly, while jaw crushers are highly effective, they can be prone to wear and tear if not properly maintained. A study found that regular maintenance can extend the lifespan of a jaw crusher by up to 30%. However, some operators overlook this, leading to higher operational costs and unexpected breakdowns.

Understanding a jaw crusher's mechanics is crucial for optimal performance. The angle between the jaws determines the size of the output material. A steeper angle results in finer output, while a shallower angle allows for larger pieces. This flexibility is a major advantage in construction and mining applications. However, if users fail to select the appropriate settings, they can experience inefficiencies or even equipment failures. Balancing the operational factors is essential for maximizing productivity.

A jaw crusher is a pivotal piece of equipment in many industries, particularly in mining and construction. Its key components are engineered to break down materials effectively. The two main parts of a jaw crusher are the stationary jaw and the movable jaw. These elements create a V-shaped cavity, where materials are crushed. When the movable jaw moves closer, it compresses the material, leading to fragmentation.

Another critical component is the toggle mechanism. This mechanism adjusts the gap between the jaws, allowing for various sizes of output material. It is vital to maintain this component for optimal performance. Additionally, the flywheel plays a significant role. It helps to balance the machine and ensure smooth operation. Without it, the crushing process can become erratic, leading to inefficient work.

Furthermore, the wear plates in a jaw crusher are essential for durability. These plates absorb the impact force during crushing. Over time, they wear down and require replacement. This need for maintenance is often overlooked. Operators should recognize the importance of regular inspections to avoid costly downtimes. Proper understanding of these components can greatly improve the jaw crusher's effectiveness and longevity.

The crushing process with a jaw crusher is fascinating and intricate. It begins when large rocks enter the machine's feeding area. The wide opening receives these materials, and a set of jaws starts to operate. One jaw remains stationary, while the other moves back and forth. This motion creates pressure that fractures the rocks.

As the rocks are crushed, they are reduced to smaller pieces. The size of these pieces depends on several factors. For instance, the distance between the jaws affects the final output size. The jaw crusher works efficiently, but operators must monitor it closely. Sometimes, unexpected blockages can occur, and they may need to halt operations. This is where reflection is crucial for improvement.

The process continues as smaller fragments exit through the crusher's bottom. These materials are then gathered for further processing or to be transported. Properly crushing rocks enhances productivity in many industries. However, attention to detail remains important. If operators overlook maintenance, efficiency drops significantly. Each step in the crushing process has its challenges, and each needs careful consideration.

A jaw crusher is a crucial piece of equipment in many industries. It primarily functions to break down large rocks into manageable sizes. The design features two "jaws," one stationary and one movable. As materials enter, they are crushed between these jaws. This action creates smaller pieces that can be further processed.

The advantages of using a jaw crusher are significant. It has a simple structure, which makes it easy to operate and maintain. This reliability is important, especially in high-demand operations. Additionally, the jaw crusher is efficient in producing uniform material sizes. This uniformity is critical for many subsequent processing steps.

However, there are areas that require reflection. While this equipment is effective, it can wear out quickly under heavy use. Regular maintenance is essential but often overlooked. Operators must monitor the machine closely to avoid potential breakdowns. This oversight can lead to downtime, affecting overall productivity. Adopting a proactive approach can enhance the lifespan of the jaw crusher and improve efficiency in operations.

Jaw crushers are widely used in various industries due to their versatility. They can effectively crush hard and abrasive materials. Common applications include mining, construction, and recycling. In mining, jaw crushers break down ore into smaller pieces for further processing. This initial size reduction is crucial for efficient extraction.

In the construction sector, jaw crushers are essential for producing aggregate. They transform large rocks into usable gravel and sand. This material is vital for building roads and structures. Additionally, in recycling applications, jaw crushers help reclaim materials from old concrete or asphalt. The process reduces waste and supports sustainable practices.

While jaw crushers are efficient, they require careful operation. Improper use can lead to decreased performance and increased wear. Regular maintenance is necessary to keep them running smoothly. Operators should be trained to recognize signs of wear or malfunction. This awareness ensures optimal operation and extends the machine's lifespan.