-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

Limestone crushers play a critical role in the construction and mining industries. They break down limestone rock into smaller fragments for various applications. John Smith, a renowned expert in aggregate processing, once stated, "A limestone crusher is essential for efficient material production."

The process begins with the extraction of limestone from quarries. Once mined, the limestone is transported to the crusher. Here, it undergoes size reduction through various mechanical means. The crusher employs jaws, hammers, or impactors to achieve this.

Understanding how a limestone crusher operates can uncover both its efficiency and limitations. Often, operators overlook maintenance, leading to reduced performance. Regular checks and adjustments are necessary to maintain optimal operation. The limestone crushing process reflects a balance between technology and human oversight. Failure to recognize this can result in inefficiencies and increased costs.

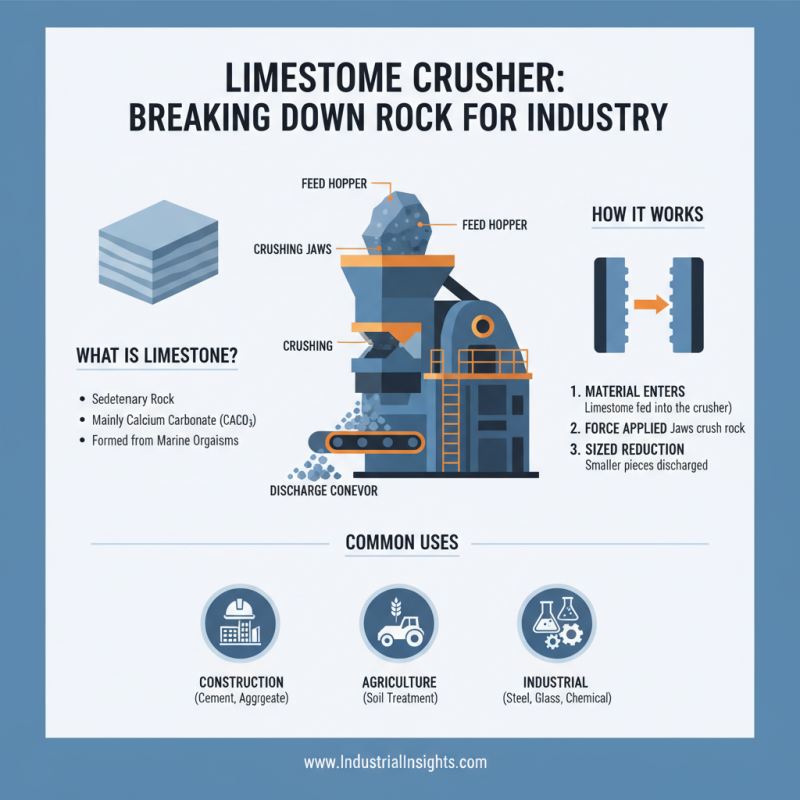

A limestone crusher is a machine designed to break down limestone into smaller pieces. Limestone is a sedimentary rock mainly composed of calcium carbonate. It is commonly used in construction, agriculture, and various industries. The crusher operates by applying force to crush the material into the desired size.

These machines come in various types, including jaw, cone, and impact crushers. Each type has a unique method of breaking limestone. For example, a jaw crusher uses two metal plates to crush the rock, while an impact crusher relies on hammers. This equipment can process limestone efficiently. However, careful operation is key to achieving optimal results.

While limestone crushers are effective, they can have limitations. Improper settings may lead to unevenly crushed materials. Additionally, dust emissions can be a concern without proper dust control measures. Regular maintenance is vital for the machine's longevity. Ensuring that the equipment runs smoothly can prevent costly downtime. All these factors need consideration for a productive operation.

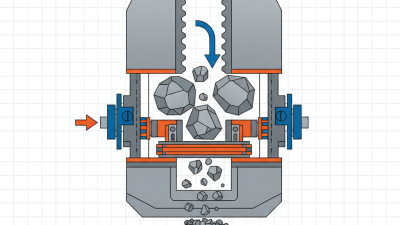

When it comes to limestone crushers, several types are available on the market. Each type serves a unique purpose and varies in design and functionality. Jaw crushers are among the most common. They crush limestone by compressing it between a fixed jaw and a moving jaw. This process breaks down larger pieces into smaller, manageable sizes.

Another popular option is the impact crusher. This machine utilizes high-speed impact to break limestone. It offers efficiency in producing fine aggregates, which can be beneficial for construction projects. Cone crushers are also used frequently. They function by squeezing the material between an eccentrically rotating cone and a crushing chamber. However, they may not be as efficient with softer limestone.

While these technologies are effective, there are challenges. Maintenance can be demanding. Operators must regularly check for wear and tear. Not everyone is well-equipped for this. Sometimes, the choice of a crusher might not suit the specific needs of a project. Assessing material characteristics is crucial yet often overlooked. Understanding these types helps make informed decisions in the limestone processing industry.

A limestone crusher is essential in many industries. It transforms large limestone rocks into small particles. This process makes limestone easier to use for construction and other applications. Understanding how limestone crushers work can help us appreciate their role.

The functioning of a limestone crusher involves several steps. Rocks enter through a feeder, usually at the top. They then go through a series of impact and compression stages. This reduces the rock size. The crushed limestone is discharged at the bottom. Despite this efficient process, it sometimes struggles with larger, harder pieces. This can cause delays and require adjustments.

An important component is the various types of crushers—jaw, impact, or cone. Each serves a unique purpose. However, selecting the right type is crucial. A poor choice can lead to inefficiencies. Maintenance also plays a vital role in ensuring optimal performance. Frequent checks can prevent costly downtimes, but often, this aspect is overlooked. In essence, understanding these details can lead to better operation and management of limestone crushers.

A limestone crusher is essential for breaking down limestone into smaller pieces. Understanding the key components of a limestone crusher helps in maximizing its efficiency.

The primary component is the crushing chamber. It houses the crushing mechanism. Inside, there are rotating hammers or jaws that do the heavy lifting. They apply force to the limestone, fragmenting it into manageable sizes. The quality of these components affects the overall performance. Regular checks are vital to ensure they function correctly.

Another critical part is the conveyor system. It transports crushed limestone for further processing or storage. The design of this system should allow for smooth movement. If it jams or malfunctions, it can slow down operations. Maintain proper alignment and check for wear frequently.

Tips: Consider the material's moisture content. Wet limestone may stick and cause blockages. Also, ensure a safety guard is in place to prevent accidents. Regular maintenance can save money and time in the long run.

| Component | Function | Material Used | Typical Size |

|---|---|---|---|

| Crusher Frame | Provides structural support | Steel or Reinforced Metal | Varies based on design |

| Crusher Jaw | Crushes and breaks down limestone | High Manganese Steel | 1 to 3 meters |

| Drive Motor | Powers the crushing mechanism | Electric Motor | 100 – 500 kW |

| Toggle Plate | Adjusts the position of the jaw | Steel | Variable |

| Adjustable Seat | Controls jaw movement and gap | Steel | Fixed |

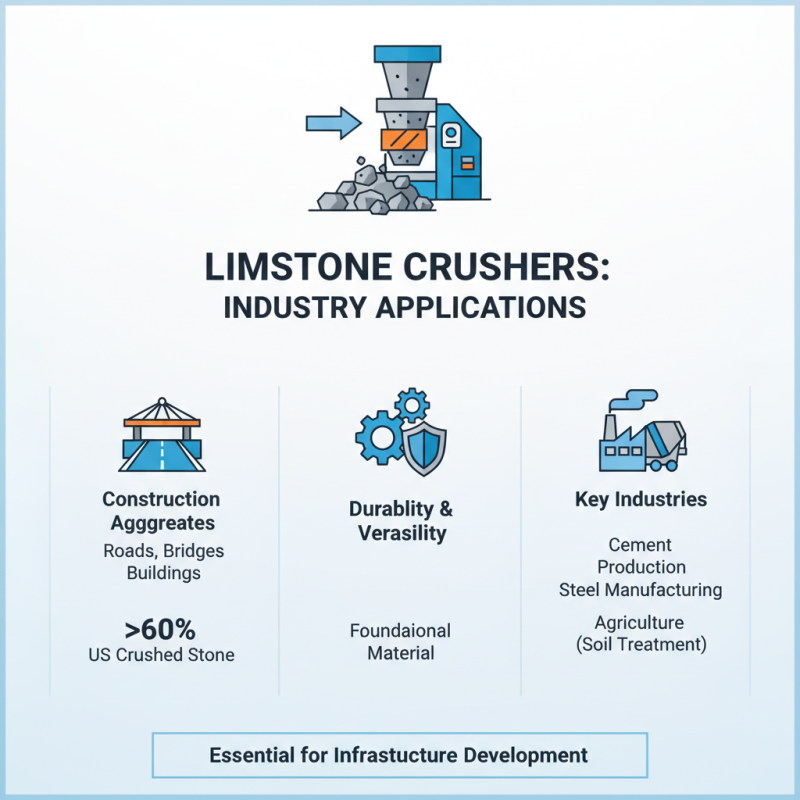

Limestone crushers have various applications across different industries. They are essential in producing aggregates for construction. According to industry reports, more than 60% of all crushed stone in the U.S. comes from limestone. This material is favored for its durability and versatility. It serves as a foundational material in roads, bridges, and buildings.

These crushers operate by pulverizing the limestone into smaller particles. The process ensures that the final product meets specific demands in size and quality. For instance, a typical crushed limestone product can range from 0.75 to 1.5 inches in size, meeting various construction specifications. However, the process isn't without its challenges. The initial investment for a limestone crusher can be significant, and ongoing maintenance is crucial.

The benefits extend beyond construction. Limestone also finds use in agriculture and chemical industries. Its ability to neutralize acids makes it valuable in soil amendment. However, there is room for improvement in energy efficiency in crushing processes. Industry studies suggest that optimizing operational techniques could decrease energy consumption by up to 30%. This aspect calls for innovation and careful consideration in future applications.