-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

In the world of construction and mining, the benefits of a Limestone Crusher cannot be overstated. John Smith, a renowned expert in material processing, once stated, "A quality Limestone Crusher can significantly enhance productivity." This sentiment rings true in many industries reliant on limestone.

Limestone Crushers offer numerous advantages for businesses. They ensure efficient material processing, reduce operational costs, and improve product quality. By using a Limestone Crusher, companies can effectively manage limestone in different stages of their operations. This machinery not only saves time but also minimizes waste, contributing to a more sustainable industry.

However, it’s important to acknowledge that selecting the right Limestone Crusher isn't always straightforward. Some businesses may overlook specific performance features or maintenance needs. Each operation is unique, and a one-size-fits-all approach might not yield the best results. Careful consideration and expert advice are crucial for making the right choice in this essential equipment.

Limestone crushers play a crucial role in various industries. They help in breaking down large rocks into smaller, manageable pieces. This process is essential for construction, agriculture, and mining. By using a limestone crusher, businesses can save time and improve material quality.

One of the significant benefits is efficiency. These machines can process large amounts of limestone quickly. Cost savings are another advantage. Reducing labor costs is possible when machinery handles bulk crushing. It can also minimize waste, which is vital in today's resource-conservative world.

Tips for using limestone crushers effectively:

1. Regular maintenance is key. Keep the machinery in good shape to avoid breakdowns. This ensures consistent performance and longevity.

2. Understanding the material is crucial. Different limestone types may require specific crushing techniques. Conduct research to determine which method suits your needs best.

Investing in a limestone crusher can lead to better product quality and increase productivity. It's essential to reflect on operational practices, ensuring you maximize the benefits while minimizing shortcomings. Analyzing your results periodically is necessary for ongoing improvement.

| Benefit | Description | Impact on Business |

|---|---|---|

| Cost Efficiency | Limestone crushers are often energy-efficient, reducing operational costs. | Lower production costs leading to increased profit margins. |

| Durability | Designed to withstand tough conditions and heavy usage. | Reduced maintenance costs and downtime. |

| Versatility | Can handle various sizes and compositions of limestone. | Applicable for a wide range of construction projects. |

| Improved Product Quality | Produces uniform and high-quality materials. | Enhances the overall quality of finished products. |

| Increased Production Capacity | Designed for high throughput and efficiency. | Supports scaling business operations and meeting demand. |

| Environmental Benefits | Often made from recyclable materials and improve resource management. | Fosters a sustainable business practice and community image. |

| Safety Features | Equipped with advanced safety mechanisms to protect operators. | Reduces workplace accidents and associated costs. |

| Ease of Use | User-friendly controls and maintenance processes. | Minimizes training time and operational errors. |

| Advanced Technology | Incorporates modern designs for enhanced performance. | Keeps the business competitive in a growing market. |

| Support and Service | Often bundled with after-sales services and support. | Ensures reliable operation and customer satisfaction. |

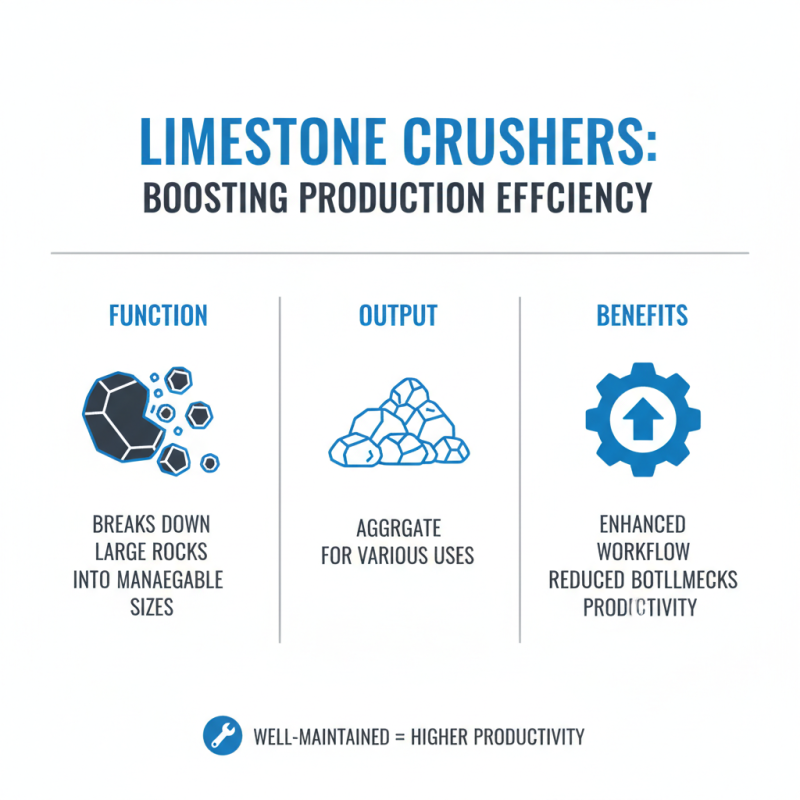

In material processing, limestone crushers play a crucial role in enhancing production efficiency. These machines break down large rocks into manageable sizes. The resulting aggregate can be used in various applications, improving workflow and reducing bottlenecks. A well-maintained limestone crusher can boost overall productivity significantly.

Tips for maintaining your limestone crusher: Regular inspections are essential. Check for wear and tear on vital components. Even minor issues can lead to inefficiencies. Keeping machinery clean can also improve performance. A clean crusher operates more effectively and requires fewer repairs over time.

Another aspect to consider is processing speed. Fine-tuning settings can lead to optimal output. However, beware of potential overproduction. It can waste resources and limit profits. Striking a balance between speed and quality is critical for success. Investing in quality training for operators improves production rates as well. Remember, knowledge is power in this industry.

Limestone crushers play a vital role in aggregate production. The cost-effectiveness of these machines greatly impacts financial outcomes for businesses. According to industry reports, limestone resources are abundant and relatively inexpensive, making them a favored raw material.

Investing in limestone crushers can improve production efficiency. Many companies report up to a 20% increase in output. This enhancement results from the machines' ability to finely crush material quickly. Operators often note that a consistent supply of finely crushed limestone can lead to significant savings on transportation and material costs.

However, not all crushers perform equally. Some models are less efficient, leading to higher operational costs. Choosing the right equipment requires careful consideration. Reports suggest that businesses often underestimate maintenance expenses. While some crushers appear cost-effective initially, they may incur high repair costs over time. Modifying and optimizing the production process using limestone can be challenging, yet extremely rewarding.

Improved particle size distribution and quality control are crucial for businesses in the limestone industry. With optimized crushers, companies can achieve a more consistent product. Studies show that a well-designed crusher improves particle size uniformity, leading to better performance in subsequent processing. Enhanced particle distribution minimizes waste and maximizes product value.

Data from industry reports highlights that businesses can boost product quality by up to 25% through efficient size reduction. This improvement often translates to fewer customer complaints and higher satisfaction rates. Fluctuations in particle size can affect material handling and overall production efficiency. Thus, investing in suitable crushing technology is necessary for staying competitive.

However, it’s important to recognize challenges that may arise. Not all crushers provide the same results. Some may require frequent maintenance, impacting operational efficiency. Regular assessments of equipment performance are essential. This reflection allows businesses to adjust strategies for better quality control. Understanding these factors can lead to more informed decisions.

In the limestone crushing industry, reducing environmental impact is crucial. Effective limestone crushers are designed to minimize emissions. Dust control systems can be integrated to reduce air pollution. Many operations, however, overlook the importance of regular maintenance. If equipment is neglected, dust can accumulate, leading to environmental concerns.

Water usage is another factor to consider. Implementing efficient water spraying systems helps control dust, but it needs constant monitoring. Sometimes, operators may not realize the amount of water being wasted. This not only drains resources but also affects nearby ecosystems.

Additionally, energy consumption is a critical aspect. Improving the efficiency of crushing operations can lead to a significant reduction in energy use. While some businesses invest in new technology, others stick to outdated methods. This can create unnecessary waste. Finding a balance between cost and sustainability requires reflection and adaptation in practices.

The article "Top 10 Limestone Crusher Benefits for Your Business" outlines the numerous advantages of incorporating Limestone Crushers into material processing operations. One key benefit is the enhanced production efficiency, which streamlines operations and increases output. Additionally, Limestone Crushers are recognized for their cost-effectiveness, particularly in aggregate production, enabling businesses to optimize their expenses while improving profitability.

Another significant advantage is the improved particle size distribution and quality control that these crushers offer, leading to superior end products. Moreover, the article highlights the reduction of environmental impact during crushing operations, making Limestone Crushers a more sustainable choice. Lastly, their versatility across various industries allows businesses to utilize these machines in diverse applications, further enhancing their operational capabilities and market competitiveness.