-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

In the world of construction and mining, the Stone Crusher Machine plays a vital role. This machine breaks down large stones into smaller, manageable pieces. According to industry expert John Smith, "The efficiency of a Stone Crusher Machine can greatly enhance production processes."

Understanding how this machinery operates is crucial. A Stone Crusher Machine uses mechanical force to crush rocks. The powered components help in reducing large materials. However, the machine's design can still improve in terms of safety and efficiency. Some machines may struggle with different types of stones. Adjustments can lead to better performance and longevity.

Proper maintenance of a Stone Crusher Machine is essential for effective operation. Neglect can lead to increased downtime. Many operators recognize the potential benefits but often overlook necessary care. Addressing these issues can ensure a smoother workflow. The journey of evolution in stone crushing technology continues, revealing areas for reflection and improvement.

A stone crusher machine is an essential piece of equipment in construction and mining. It is designed to reduce large rocks into smaller, manageable pieces. These machines come in various types, including jaw crushers, cone crushers, and impact crushers. Each type serves a specific purpose in the crushing process.

According to a recent industry report, the global market size for stone crushers is expected to reach $4.5 billion by 2026. This growth correlates with the rising demand for construction materials. The crushing process typically involves the feeding of raw stones into the machine. The stones are then crushed between two surfaces. In this way, they are transformed into gravel, sand, or other aggregate materials. It’s important to note that efficiency can vary based on design and application.

Working with stone crushers does require careful considerations. Incorrect usage can lead to mechanical failures or inefficiencies. For instance, operators need to monitor the feed size constantly. If the material is too large, the machine may not perform optimally. Regular maintenance is also crucial to avoid downtime. The crushing process, while effective, can produce dust and noise pollution, which are often overlooked issues in many operations.

Stone crusher machines play a vital role in construction and mining. They break down large rocks into smaller, manageable pieces. There are several types of stone crusher machines available, each designed for specific tasks.

Jaw crushers are one of the most common types. They work by placing rocks between two heavy plates. The plates crush the stones as they move closer together. These machines are great for primary crushing. Yet, they might struggle with very hard materials.

Another popular type is the cone crusher. This machine uses a rotating cone inside a bowl. It crushes stones from the inside out. Cone crushers are excellent for secondary and tertiary crushing. However, they can be expensive to maintain. Impact crushers are also frequently used. They break rocks using high-speed impact forces. These machines can process a wide range of materials, but are sometimes less efficient with larger stones. Each type has its advantages and challenges, making the selection process crucial for optimal results.

Stone crusher machines play a crucial role in various industries. They are primarily used to break down large rocks into smaller pieces. This process is essential for construction, mining, and recycling. Understanding how these machines operate can enhance their effectiveness.

Stone crusher machines typically work by using mechanical force. Crushers have jaws that compress stones. As the stones enter, they are crushed into smaller fragments. Techniques like impact and cone crushing are common. Each method has its advantages. The type of stone and desired size often dictate the best choice.

Tips: Always monitor the machine's performance. Regular maintenance keeps it running smoothly. Check your output regularly. Consider adjusting settings to optimize results.

The operation of stone crushers can be noisy and dusty. Workers should wear appropriate safety gear. It is important to ensure that the site is well-ventilated. Incorrect handling can lead to inefficiencies. Sometimes, operators overlook vital checks before starting. A brief inspection can save time and resources later.

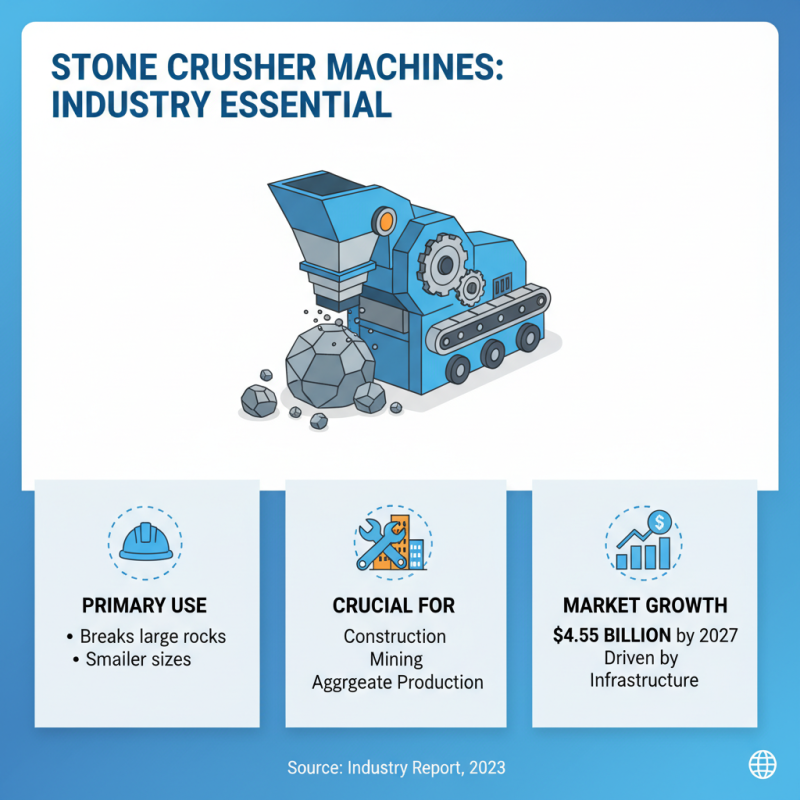

Stone crusher machines play a vital role in various industries. They are primarily used for breaking down large rocks into smaller, manageable sizes. This process is crucial for construction, mining, and aggregate production. According to a recent industry report, the global stone crushing equipment market is projected to reach $4.55 billion by 2027, driven by increased infrastructure spending.

In construction, stone crushers are used to create aggregates for concrete and asphalt. They ensure that the materials meet the required standards for strength and durability. However, choosing the right type of stone crusher can be challenging. Each machine serves different purposes. For instance, jaw crushers handle larger stones, while impact crushers are more suitable for softer materials.

Environmental concerns also arise. Emissions from stone crushing can affect air quality. Adapting cleaner technologies may be necessary. Moreover, maintenance of these machines requires regular attention. Neglect can lead to increased operational costs. According to industry analyses, around 20% of maintenance issues could disrupt production schedules. Therefore, understanding these machines and their applications is essential for maximizing efficiency and mitigating risks.

Stone crushers are essential machines in construction and mining industries.

Their operation requires attention to maintenance and safety to prevent accidents. Regular checks on vital components can enhance longevity.

Daily inspections for wear and tear are crucial. Lubricating moving parts reduces friction and ensures smooth operation. Operators should also be aware of potential hazards, like flying debris. Using appropriate safety gear, such as helmets and goggles, is a must.

Overloading the machine can lead to breakdowns.

Operators may underestimate the impact of this. Proper training is vital for safe operation. Keeping the work area clean minimizes risks of slips and falls. Stone crushers play a significant role, but safe practices should never be overlooked.