-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

In the rapidly evolving landscape of construction and mining, the demand for efficient and reliable Stone Crushing Equipment has never been greater. According to a report by Allied Market Research, the global stone crushing equipment market is projected to reach $8.95 billion by 2026, growing at a CAGR of 8.3% from 2019 to 2026. This surge is primarily driven by the increasing use of crushed stones in various applications such as road construction, building construction, and mining operations.

Industry expert Dr. John Smith, a renowned authority in aggregate production technology, emphasizes the importance of optimizing operations within this sector. He states, “The efficiency of stone crushing equipment plays a critical role in determining the overall productivity and profitability of construction projects.” This assertion underscores how advancements in technology can greatly enhance the performance and sustainability of stone crushing processes.

As we delve into the Ultimate Guide to Stone Crushing Equipment, we will explore the latest innovations, operational best practices, and strategic insights necessary for optimizing efficiency in stone crushing operations. Understanding these elements can empower industry professionals to make informed decisions, enhance productivity, and ensure the sustainable use of resources in this vital sector.

Stone crushing equipment plays a crucial role in various industries, especially in construction and mining. This equipment is designed to reduce large rocks into smaller, manageable pieces, making it easier to transport and utilize in different applications. The main types of stone crushing equipment include jaw crushers, cone crushers, impact crushers, and mobile crushers, each serving specific purposes within the crushing process.

Jaw crushers are commonly used for primary crushing operations, featuring two opposing jaws that crush material as it enters the chamber. This type of equipment is ideal for breaking down larger stones into smaller fragments. Cone crushers, on the other hand, are typically employed for secondary and tertiary crushing. They utilize a rotating cone to compress material, effectively reducing size and providing a more uniform product. Impact crushers utilize rapid impacts to crush stones, making them suitable for a variety of materials, including softer minerals.

Mobile crushing equipment has gained popularity due to its flexibility and ease of use on job sites. These machines can be transported easily and set up quickly, making them perfect for projects that require frequent relocation. Overall, understanding the different types and functions of stone crushing equipment is essential for optimizing operations, ensuring efficiency, and meeting project demands.

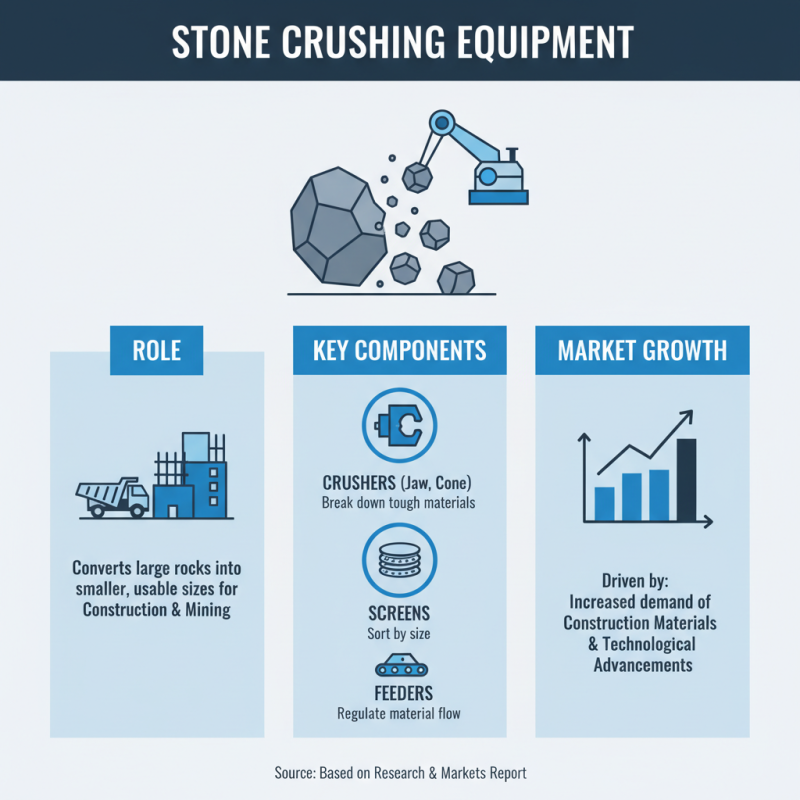

Stone crushing equipment plays a crucial role in the construction and mining industries by converting large rocks into manageable sizes for further processing. Key components of this equipment include crushers, screens, and feeders, each serving a distinct function that contributes to overall operational efficiency. According to a report by Research and Markets, the stone crushing equipment market is expected to grow significantly, driven by increasing demand for construction material and advancements in technology. Crushers, such as jaw and cone types, are designed to break down the toughest materials, effectively reducing their size for subsequent operations.

Screens are essential for separating the crushed material into various grades, ensuring the output meets the specifications required for specific applications. Effective screening can enhance productivity by preventing the accumulation of oversized materials that may hinder the crushing process. Feeders, on the other hand, are instrumental in controlling the flow of raw materials into the crusher, optimizing throughput and minimizing operational interruptions. A study by Global Market Insights indicates that improvements in feeder technology can increase processing efficiency by up to 25%. These components work synergistically to ensure that stone crushing operations are efficient, reliable, and capable of meeting the growing demands of modern infrastructure projects.

Efficiency in stone crushing operations is significantly influenced by several key factors. One primary aspect is the choice of equipment and technology used. According to industry reports, modern crushing plants that incorporate advanced technology can increase processing efficiency by up to 30%. The integration of automated systems and predictive maintenance tools not only enhances operational efficiency but also reduces downtime, providing a more reliable production schedule.

Another crucial factor is the material characteristics being processed. The hardness, size, and moisture content of stones can directly impact crusher performance. For instance, softer materials require less energy to crush, while harder rocks may necessitate more robust machinery, ultimately affecting production rates. A study by the National Stone, Sand and Gravel Association indicates that optimizing the feed material size can improve throughput by as much as 20%.

Tips: Regularly monitor equipment performance and adjust operational parameters accordingly. This approach can help in identifying inefficiencies and optimizing output. Additionally, investing in high-quality wear parts can reduce unexpected downtime and maintenance costs, ensuring smooth and efficient operations.

Effective maintenance practices are essential for ensuring optimal performance in stone crushing operations. According to a report by the Mining Industry Council, timely maintenance can reduce equipment downtime by up to 30%, significantly enhancing production efficiency. Regular inspections and adherence to manufacturer guidelines not only prolong the lifespan of machinery but also promote a safer working environment. It's crucial to conduct routine checks on wear parts, hydraulic systems, and other critical components to identify potential issues before they escalate.

Tips: Implement a daily checklist for operators to assess the condition of machinery at the start of each shift. This simple practice can facilitate early detection of wear and tear, ultimately saving costs on repairs and minimizing operational disruptions.

In addition to equipment inspections, lubrication is another critical aspect of maintenance that should not be overlooked. A study published by the International Journal of Engineering outlines that proper lubrication can improve operational efficiency by up to 25%. Using the right type and amount of lubricant can reduce friction and prevent overheating, thereby enhancing machine performance. Moreover, cleanliness around equipment is vital to preventing material buildup that can lead to damage and inefficiency.

Tips: Schedule consistent lubrication intervals and maintain a clean working area to prevent debris from accumulating around the machinery. This proactive approach not only keeps equipment running smoothly but also fosters a safer and more organized workplace.

The stone crushing industry is undergoing a significant transformation as technology continues to advance. One of the most promising future trends is the integration of automation and artificial intelligence in crushing operations. By implementing sophisticated monitoring systems, companies can optimize equipment performance, reduce downtime, and enhance overall efficiency. Automated processes can analyze real-time data to ensure precise adjustments are made during operation, ultimately leading to increased production rates and lower operational costs.

Another emerging trend is the focus on sustainability within the stone crushing sector. As environmental regulations tighten, manufacturers are developing equipment that minimizes carbon footprints and energy consumption. Innovations such as energy-efficient crushers and dust control systems not only comply with regulations but also enhance the corporate responsibility efforts of companies. Additionally, the use of recycled materials in the production of new machinery further contributes to a more sustainable approach in the industry, signaling a shift towards greener operations. These advancements are not just beneficial for the environment; they also present new opportunities for competitive advantage in a rapidly evolving market.

| Equipment Type | Capacity (tons/hour) | Power Consumption (kW) | Maintenance Frequency (months) | Future Trends |

|---|---|---|---|---|

| Jaw Crusher | 50-500 | 75-500 | 6 | Automation and smart technology integration |

| Impact Crusher | 30-400 | 50-300 | 4 | Recycling materials for reduced waste |

| Cone Crusher | 50-800 | 75-600 | 5 | Advanced control systems for enhanced efficiency |

| Mobile Crusher | 10-300 | 30-250 | 3 | Increased mobility and flexibility on site |

| Vibrating Screen | 30-600 | 10-50 | 2 | Enhanced sorting capabilities with AI integration |