-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

Choosing the right Rock Crushing Equipment is crucial for any construction or mining project. It impacts efficiency, costs, and output quality. With a variety of options available, making a decision can feel overwhelming. Consider the type of material you will be crushing and the desired size of the end product. Each machine serves a specific purpose.

Look beyond brand names and focus on performance. While durability is essential, think about the energy efficiency and maintenance costs. Sometimes, the most reliable equipment may not come from the most famous brands. Also, consider the support provided by manufacturers. This can influence your operational downtime.

Finally, do not overlook the importance of user reviews and testimonials. They can provide valuable insights into performance over time. Understand that no equipment is perfect. Each will have limitations. Evaluating these aspects deeply can lead to a more informed decision. Investing time in research pays off in the long run.

When selecting rock crushing equipment, several key factors must be considered to ensure optimal performance. Understand the material type you will be processing. Harder materials require robust machinery, while softer materials can be managed with less intense equipment. The performance capacity is crucial. According to industry reports, equipment that offers a processing capacity of 200 tons per hour is ideal for medium-scale operations.

Another important aspect is the operational cost. Maintenance and energy expenses can add significant overhead. Industry data suggests that poorly selected equipment can lead to up to a 30% increase in operational costs. Assessing the feed size is also vital. A machine may work efficiently with a certain input size, but performance can dramatically decline if dimensions are mismatched.

Consider the environmental impact as well. The noise and emissions from rock crushing can be considerable. Equipment choices can help mitigate these issues. Investing in technology that lowers dust and noise can be beneficial. However, the initial cost often deters purchase. Many companies may overlook this aspect, ultimately affecting compliance and community relations. Balancing cost with sustainability is challenging yet necessary in today's market.

This chart illustrates key characteristics to consider when selecting rock crushing equipment including capacity, power, weight, cost, and maintenance frequency. Each factor plays a critical role in determining the suitability and effectiveness of the equipment in various operational settings.

When selecting rock crushing equipment, understanding different types is crucial. Jaw crushers are popular for their ability to handle large rocks. They provide a consistent output size. According to industry reports, around 20% of the global market uses this equipment for primary crushing.

Cone crushers are another key type. They excel in producing refined, smaller aggregates. The data shows that they are favored in secondary and tertiary crushing processes, handling materials like granite and basalt. Their efficiency improves with modern advancements, yet they can be sensitive to feed variations.

Impact crushers stand out for their versatility. They are effective for softer rocks and have become essential in recycling applications. Industry statistics indicate that their use increased by 15% over the last five years in construction projects. However, operators often face challenges in achieving uniformity. Inefficient settings can lead to inconsistent particle sizes, prompting users to reassess their techniques. It's vital to evaluate equipment suitability based on specific project needs.

| Type of Equipment | Application | Advantages | Considerations |

|---|---|---|---|

| Jaw Crusher | Primary crushing of large rocks | High reduction ratio, robust construction | Can be less effective with harder materials |

| Cone Crusher | Secondary and tertiary crushing | Excellent shape and size control | Requires more maintenance than other types |

| Impact Crusher | Crushing of medium to soft materials | High efficiency, suitable for recycling | May produce more fines than other crushers |

| Hammer Mill | Grinding and crushing of smaller rocks | Versatile, simple structure | Not suitable for very hard materials |

| Vertical Shaft Impact (VSI) Crusher | Sand making and shaping | Produces high-quality sand and aggregates | High operational costs |

When evaluating the capacity and size requirements for rock crushing equipment, several factors come into play. Understanding the type of materials you will crush is crucial. For example, the compressive strength of the rock can dictate the selection process. According to industry reports, granite typically requires crushers with at least a 40 ton per hour capacity.

Project size also influences machinery choice. If you're working on a large site, investing in high-capacity crushers makes sense. They can process more materials efficiently, saving time. However, smaller projects might benefit from more compact models, which offer flexibility. These typically range between 10 to 15 ton per hour, as noted in various construction equipment reviews.

Consider the feed size as well. Larger materials need strong, robust equipment. A common recommendation is to have feeders with a capacity that exceeds the expected feed size by about 25%. This helps avoid bottlenecking. While aiming for high capacity is important, underestimating the demands can lead to unexpected breakdowns. Thus, careful analysis of project specifics is essential for optimal equipment selection.

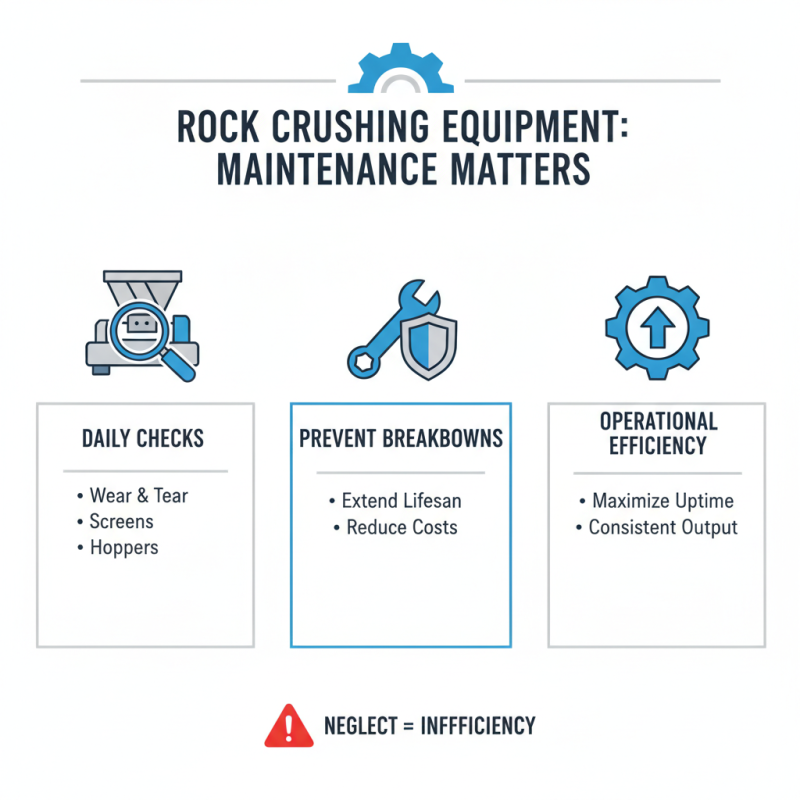

Choosing the right rock crushing equipment is critical. Maintenance is a major component of this decision. Regular maintenance can prevent costly breakdowns. Equipment should be checked daily for wear and tear. Parts like screens and hoppers need attention. Neglect can lead to operational inefficiencies.

Operational costs are another vital aspect. Fuel consumption impacts your budget significantly. A machine that uses too much fuel can quickly become a financial burden. Efficiency ratings can help gauge this. However, they often don't tell the full story. Regular assessments are necessary to avoid surprises.

Consider the environment where the equipment will operate. Dust, moisture, and temperature can affect performance. You may spend more on maintenance in harsher conditions. Think about long-term usage and adaptability. Changes in project scope might require different equipment. Sometimes, what works best may evolve over time. Decisions should not be made lightly.

When choosing rock crushing equipment, safety features are vital.

Equipment must comply with industry standards. Look for machines that are equipped with

overload protection. This prevents unexpected failures and injuries.

Emergency stop buttons should be easily accessible. Operators should not struggle to halt machinery in emergencies.

Another crucial safety aspect is dust control. Rock crushing generates dust

that can harm health. Effective dust suppression systems are essential. Ensure that the equipment has proper

dust extraction features. This not only protects workers

but also the surrounding environment.

Consider operator training as well. Even with the best equipment, human error can lead to accidents. Proper

training ensures that operators understand safety protocols. A lack of knowledge can lead to oversights.

Therefore, prioritize comprehensive training

programs for all staff. This investment promotes a safer working environment.