-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

In the dynamic world of construction and mining, the efficiency of material processing plays a crucial role in determining overall project success. As experts in the field emphasize, the right equipment can significantly impact productivity. John Smith, a well-respected industry specialist, once stated, “Investing in high-performance Rock Crusher Machines is essential for achieving fast and reliable results in any production setting.” His insight reflects the growing importance of selecting the appropriate machinery for crushing operations.

Rock Crusher Machines are not only vital for reducing large stones to usable materials, but they also enhance operational efficiency and ensure high-quality outputs. With advancements in technology, many of these machines now feature innovative designs and capabilities that elevate their performance. From compact models suitable for smaller projects to heavy-duty machines designed for large-scale operations, the variety available today allows operations to optimize their processes.

In this article, we will explore the top 10 Rock Crusher Machines that stand out for their efficient crushing abilities and high performance. By examining each machine's features, we aim to provide insights that can guide industry professionals in making informed decisions that will drive productivity and efficiency in their projects.

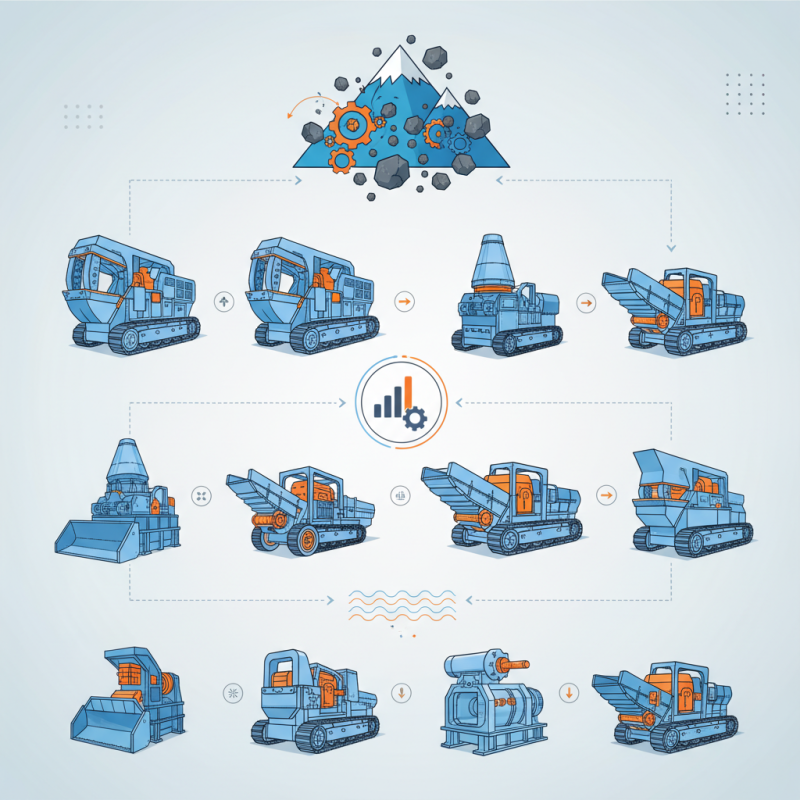

Rock crusher machines play a critical role in various industries, primarily in mining, construction, and recycling. These machines are designed to break down large rocks into smaller, more manageable pieces, which can then be processed further or utilized in different applications. According to a report by the Global Mining Guidelines Group, the demand for effective rock crushing equipment is projected to grow significantly due to the increasing need for mineral resources in infrastructure development. This growth is also spurred by the rising popularity of recycling practices, which necessitate the use of crushers to process concrete, asphalt, and other materials.

The efficiency of rock crusher machines is often measured by their throughput and reduction ratio. For instance, modern impact crushers can achieve a reduction ratio of up to 30:1, thus ensuring maximum resource recovery and minimizing operational costs. The global market for rock crushing equipment is expected to reach approximately $4 billion by 2025, driven by advancements in technology that enhance the performance and efficiency of crushing processes. Furthermore, according to a research study by Mordor Intelligence, the increasing emphasis on renewable resources and sustainability is propelling the adoption of mobile and modular crushing units, allowing for on-site processing and reduced transportation costs.

| Machine Type | Max Input Size (inches) | Output Size (inches) | Capacity (tons/hour) | Weight (lbs) | Application |

|---|---|---|---|---|---|

| Jaw Crusher | 12 | 6 | 100 | 5000 | Primary crushing of hard materials |

| Cone Crusher | 10 | 3 | 150 | 8000 | Secondary and tertiary crushing |

| Impact Crusher | 8 | 2 | 200 | 6000 | Breaking of softer materials |

| Vertical Shaft Impact (VSI) Crusher | 6 | 1 | 50 | 4000 | Sand production and shaping |

| Hammer Mill | 5 | 0.5 | 300 | 3500 | Material pulverization |

| Roll Crusher | 8 | 4 | 120 | 4500 | Medium hardness material processing |

| Gyratory Crusher | 14 | 6 | 250 | 10000 | Primary crushing in large volumes |

| Mobile Crusher | 12 | 5 | 80 | 7000 | On-site crushing and construction |

| Mini Crusher | 6 | 2 | 40 | 1500 | Small scale demolition and recycling |

| Glass Crusher | 5 | 1 | 60 | 3500 | Recycling and waste management |

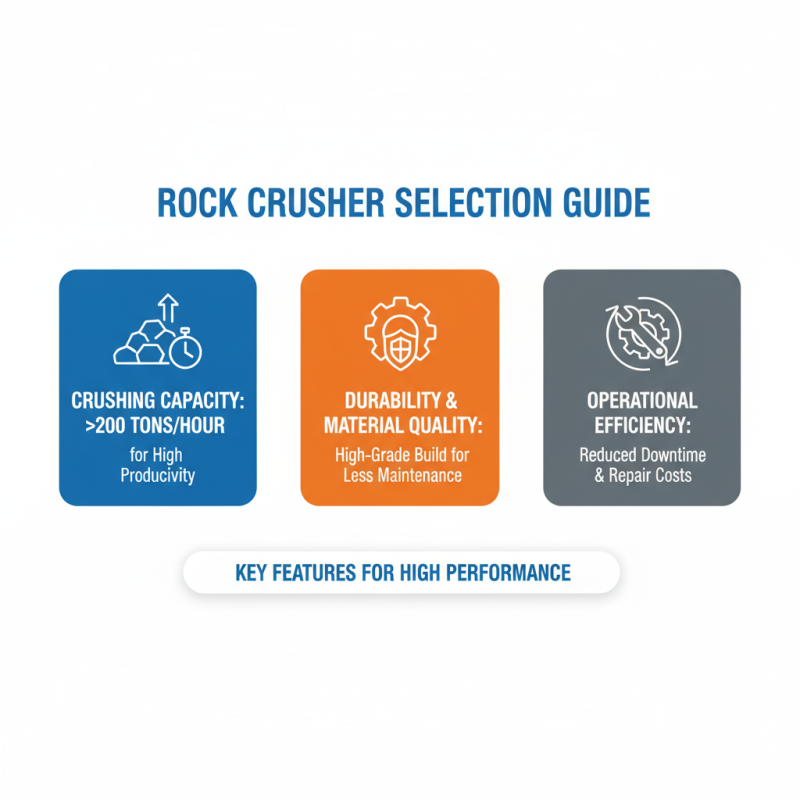

When selecting a rock crusher, several key features play a pivotal role in ensuring efficient crushing and high performance. First and foremost, the crushing capacity is essential. A high-capacity crusher can significantly increase productivity, with industry reports indicating that machines with capacities over 200 tons per hour tend to yield better operational efficiency. Additionally, durability and material quality are crucial factors; choosing a crusher built from high-grade materials can reduce the frequency of repairs and maintenance.

Another critical aspect to consider is the size and weight of the machine. Larger crushers generally offer better performance, but they can also impact mobility and installation time on job sites. Therefore, it’s important to strike a balance between size, power, and operational flexibility. Also, consider the ease of access for service maintenance, as this can minimize downtime and optimize the overall productivity of your operations.

Tips: Always evaluate the power consumption of the rock crusher; aiming for a machine that provides high output with lower energy costs can lead to significant savings over time. Moreover, look for crushers that offer versatile crushing methods, allowing for a wider range of applications, which can enhance the operational adaptability in various work environments.

When evaluating rock crusher machines, it's essential to consider various factors that contribute to their efficiency and performance. The top machines on the market showcase a range of features designed to optimize crushing capability while ensuring durability. Key specifications to compare include the type of crushing mechanism—such as jaw, cone, or impact—and their respective output capacities. Each type has its strengths; for instance, jaw crushers are often favored for their ability to handle large rocks, while cone crushers excel in producing finely crushed material.

In addition to the crushing mechanism, operational features like adjustable settings and ease of maintenance are critical for performance. Machines that offer quick setup and adjustment capabilities not only reduce downtime but also enhance productivity in demanding work environments. Furthermore, considerations such as energy efficiency and noise levels are increasingly important, as companies strive to minimize their environmental footprint. By assessing these factors comprehensively, businesses can identify the most suitable rock crusher machines that align with their operational needs and budget constraints.

When evaluating rock crushers, performance metrics play a crucial role in determining their efficiency and effectiveness in material processing. Key performance indicators include throughput capacity, reduction ratio, and operational cost. Throughput capacity measures the amount of material that can be processed in a given time frame, making it a vital factor for any operation looking to maximize output. A higher reduction ratio indicates a machine's ability to produce smaller aggregate sizes from larger rocks, contributing to better material quality.

For those seeking to optimize performance, consider the following tips. First, regularly maintain and inspect your rock crusher to ensure it operates at peak efficiency. This includes checking for wear and tear on important components, which can drastically affect performance if left unaddressed.

Second, assess the feed material's characteristics to ensure optimal size and composition for your specific crusher type, as mismatched materials can lead to reduced efficiency and increased wear.

Another essential metric is energy efficiency, which assesses how much power is consumed relative to the output produced. Investing in crushers that deliver high energy efficiency not only reduces operational costs but also supports sustainability goals.

By focusing on these performance metrics and best practices, operators can make informed decisions that enhance the productivity and longevity of their rock crushing equipment.

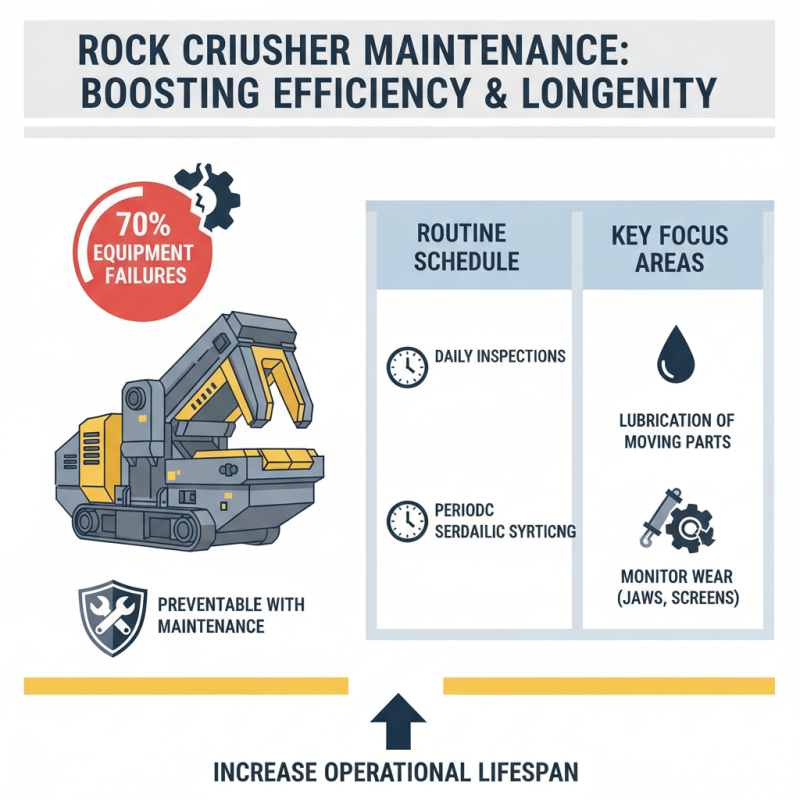

To maximize the efficiency and longevity of rock crusher machines, regular maintenance is paramount. According to industry reports, approximately 70% of equipment failures can be attributed to inadequate maintenance practices. Establishing a routine maintenance schedule that includes daily inspections and periodic servicing can significantly enhance a crusher's operational lifespan. Key areas to focus on include checking hydraulic systems, regular lubrication of moving parts, and monitoring wear levels on vital components, such as jaws and screens.

In addition, implementing predictive maintenance strategies can help in identifying potential issues before they lead to costly breakdowns. Utilizing technologies such as vibration analysis and thermal imaging can provide insights into the operating conditions of the machinery. A study indicated that organizations using predictive maintenance can decrease downtime by up to 30% and minimize repair costs by up to 25%. By ensuring each component of the rock crushing equipment operates at peak performance, operators can not only extend the life of their machines but also enhance overall productivity and efficiency in operations.