-

Home

-

Products

-

Projects

-

Solutions

-

News

-

Services

-

About Us

-

Blog

-

Contact Us

Inquiry

Form loading...

When it comes to aggregate production and construction, selecting the right equipment is crucial for achieving efficiency and performance. One of the most important pieces of machinery in this field is the Stone Crusher Machine. These machines come in various types, each designed to handle different applications and materials. Understanding the distinctions between these types can significantly affect the productivity and cost-effectiveness of your operations.

In this article, we will explore the top 10 types of Stone Crusher Machines, focusing on their specific functions, advantages, and suitability for different crushing tasks. Whether you are in the market for a machine to process raw materials for construction, recycling, or mining, knowing which Stone Crusher Machine fits your needs is essential. By the end of this guide, you will have a clearer picture of the options available to you, helping you make an informed decision that aligns with your business goals and operational demands.

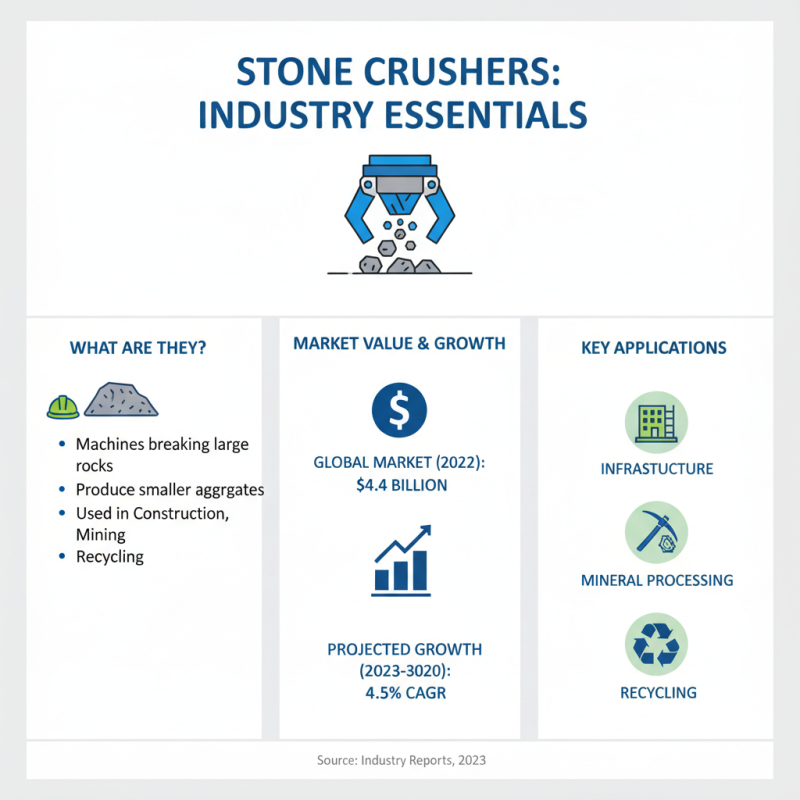

Stone crushers are essential machines in various industries, primarily utilized for breaking down large rocks into smaller aggregates for construction, mining, and recycling purposes. The global stone crushing equipment market was valued at approximately $4.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of around 4.5% from 2023 to 2030, reflecting the industry's expanding role in infrastructure development and mineral processing. Different types of stone crushers are designed to handle various applications, making it crucial to choose the right one based on specific operational needs.

Jaw crushers are particularly effective for primary crushing, offering robustness and high throughput. Cone crushers, on the other hand, excel at secondary and tertiary crushing stages, particularly in mineral processing. Impact crushers are ideal for shaping aggregate material, providing versatility in dimensions and sizes. According to industry reports, the demand for mobile crushers is increasing, driven by their ease of transport, flexibility in different terrains, and ability to perform on-site processing, which significantly reduces transportation costs. Each of these machines addresses distinct challenges, and understanding their applications is key to maximizing efficiency and productivity in stone-related projects.

When selecting a stone crusher machine, it is crucial to understand the various types available, as each serves different purposes and operates under distinct principles.

Jaw crushers, for instance, are ideal for primary crushing due to their high compressive strength, making them suitable for hard rocks.

Cone crushers, with their versatile design, excel at secondary crushing and can process materials of varying hardness and viscosity efficiently.

Impact crushers are another category worth considering, especially for those looking to produce finer aggregates. They work by utilizing high-speed impact forces, making them effective in reducing large stones to smaller sizes.

Furthermore, vertical shaft impact (VSI) crushers are great choices for creating sand from stone, offering a unique mechanism that nourishes material shape and gradation.

Tips: When choosing a stone crusher, consider the material you'll be processing and the desired output size. It’s also essential to review the operational costs and maintenance involved with different machine types. Always align your machine selection with your specific production requirements for optimal performance.

When choosing a stone crusher machine, several factors must be considered to ensure it meets your operational needs effectively. Firstly, the material type to be processed plays a crucial role in selecting the appropriate machine. Different machines are designed for specific materials — whether it's hard granite or softer limestone, understanding the hardness and abrasiveness of the material helps determine the level of durability and efficiency required from the crusher.

Another important factor is the desired output size and capacity. Different projects may require various sizes of crushed stone, and machines come with varying capabilities. Evaluating your project's specifications will guide you in selecting a machine that can consistently produce the desired output without causing unnecessary delays or reprocessing.

Tips: Always consider the maintenance and operational costs associated with the machine. A more expensive, high-performance crusher might seem appealing, but if the ongoing costs exceed your budget, it may not be the best choice. Additionally, consult with industry professionals and analyze user reviews to make an informed decision, as real-world experiences often highlight strengths and weaknesses not evident in technical specifications alone.

Prioritizing your actual needs over marketing hype can lead to more satisfying results.

When considering stone crusher machines, it is essential to understand the various types available and their specific functionalities. Generally, stone crushers can be classified into two main categories: primary and secondary crushers. Primary crushers, such as jaw crushers, are designed to handle large pieces of rock, breaking them down into manageable sizes for further processing. These machines are known for their durability and efficiency in crushing heavier materials. In contrast, secondary crushers, such as cone or impact crushers, are tailored for refining the output from primary crushers. They produce finer aggregates, making them ideal for applications that require a specific particle size.

Another critical aspect to consider is the operational mechanism of each type. Jaw crushers use a compressive force, which allows them to break down tough materials effectively. On the other hand, cone crushers utilize a combination of compression and shear forces, making them suitable for a wider range of material types and sizes. Impact crushers operate differently, relying on high-velocity impacts to break the material, which is particularly effective for softer stones. Understanding these differences helps in selecting the right type of stone crusher for your specific needs, ensuring optimal performance and efficiency in your operations.

| Machine Type | Application | Capacity (Tons/Hour) | Weight (Kg) | Power Range (kW) |

|---|---|---|---|---|

| Jaw Crusher | Primary Crushing | 50-150 | 1000-1500 | 75-150 |

| Cone Crusher | Secondary Crushing | 40-100 | 1200-2000 | 90-200 |

| Impact Crusher | Medium Crushing | 30-80 | 800-1500 | 75-160 |

| Vertical Shaft Impact Crusher | Sand Making | 20-60 | 1000-2500 | 110-250 |

| Roll Crusher | Fine Crushing | 10-50 | 600-1200 | 30-100 |

| Gyratory Crusher | Primary Crushing | 150-400 | 2500-6000 | 200-500 |

| Hammer Crusher | Material Size Reduction | 40-60 | 900-1900 | 55-150 |

| Mobile Crusher | Site-Specific Crushing | 20-100 | 1500-3000 | 60-150 |

| Stationary Crusher | Fixed Plant Operations | 80-200 | 2000-5000 | 150-300 |

| Crusher Bucket | On-Site Material Processing | 5-20 | 300-800 | 15-50 |

When it comes to operating stone crusher machines, maintenance is crucial to ensuring their longevity and efficiency. Regular inspections play an important role; operators should check for any signs of wear and tear, particularly on critical components such as belts, bearings, and jaws. Lubrication should be performed according to the manufacturer's recommendations, as this significantly reduces friction and helps prevent overheating. Additionally, cleaning the machine regularly from dust and debris helps maintain optimal performance and prevents blockages in the system.

In terms of operational tips, it's essential to match the type of stone crusher to the material being processed. Each machine has its own strengths and is designed for specific applications, such as primary crushing or secondary crushing. Operators should also be mindful of the feed rate; overloading the machine can lead to excessive wear and potential breakdowns. Training staff on proper operational techniques and safety measures ensures that the equipment is used effectively and risks are minimized. By adhering to these maintenance and operational tips, you can significantly enhance the performance and lifespan of your stone crusher machinery.

This bar chart represents the different types of stone crusher machines and their respective efficiencies based on operational requirements. Choosing the right type can optimize your crushing needs.